How Accurate Dial & Nameplate Boosted Throughput with Toolpath’s AI-Driven Estimating and CAM Automation

Industry

Manufacturing

Challenge

Manual quoting processes at Accurate Dial & Nameplate took weeks, severely limiting new business intake and causing bottlenecks. Operations Manager James Dyer had to juggle multiple roles, further straining resources.

Results

By implementing Toolpath’s AI-driven estimating and CAM automation, Accurate Dial & Nameplate dramatically reduced quoting time from weeks to hours and RFQ-to-chip time from weeks to days. The company now faces a new bottleneck, spindle capacity, with a spindle schedule booked three months out.

Key Product

Toolpath Estimating, Toolpath CAM

Toolpath has helped me offer quotes at a fast turnaround time and also helped me with the majority of my programming.

James Dyer

Operations Manager

Before Toolpath my biggest bottleneck was quoting. After Toolpath my biggest bottleneck is spindle capacity.

James Dyer

Operations Manager

It would take me weeks to quote, then to program, then to run… My throughput is now significantly higher, because I can quote in a matter of minutes and get it on the machine in a matter of days.

James Dyer

Operations Manager

Who are Accurate Dial?

Accurate Dial & Nameplate is a family-run aerospace and defense manufacturer, specializing in dial, nameplate, and badging work since 1958. Based in Glendale, LA, the company employs 25 people and is ISO and AS 9100 certified with ITAR registration.

The Challenge

Accurate Dial & Nameplate, faced significant challenges with their manual quoting processes. These processes took weeks to complete, causing severe bottlenecks that limited their ability to intake new business. Operations Manager James Dyer, who wore multiple hats including quoting, programming, and running machines, found the manual process overwhelming and inefficient.

The Solution

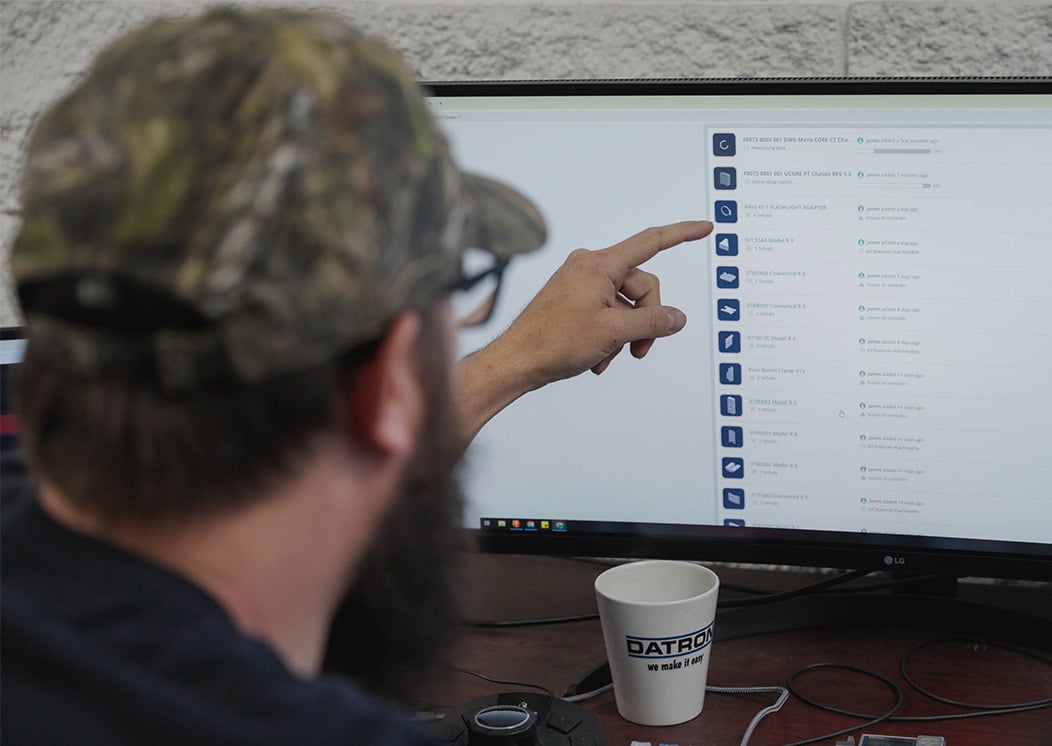

Accurate Dial & Nameplate decided to address their bottlenecks by adopting Toolpath’s AI-driven estimating and CAM automation. The decision came after mapping out James’s quoting and programming workflow and benchmarking the time taken before Toolpath. They deployed Toolpath Estimating for fast cost and DFM (Design For Machining) feedback and Toolpath CAM for ready-to-simulate toolpaths inside Autodesk Fusion. James Dyer noted:

'Before Toolpath my biggest bottleneck was quoting. After Toolpath my biggest bottleneck is spindle capacity.'

The Results

After implementing Toolpath, Accurate Dial & Nameplate saw a dramatic reduction in quoting time from weeks to hours and RFQ-to-chip time from weeks to days. Their spindle schedule is now booked three months out, shifting the bottleneck from paperwork to machine capacity. James Dyer remarked, 'It would take me weeks to quote, then to program, then to run… My throughput is now significantly higher, because I can quote in a matter of minutes and get it on the machine in a matter of days.' The company now enjoys a greater share of high-margin direct work and less reliance on marketplaces.