AI CAM That Plans, Estimates & Programs CNC

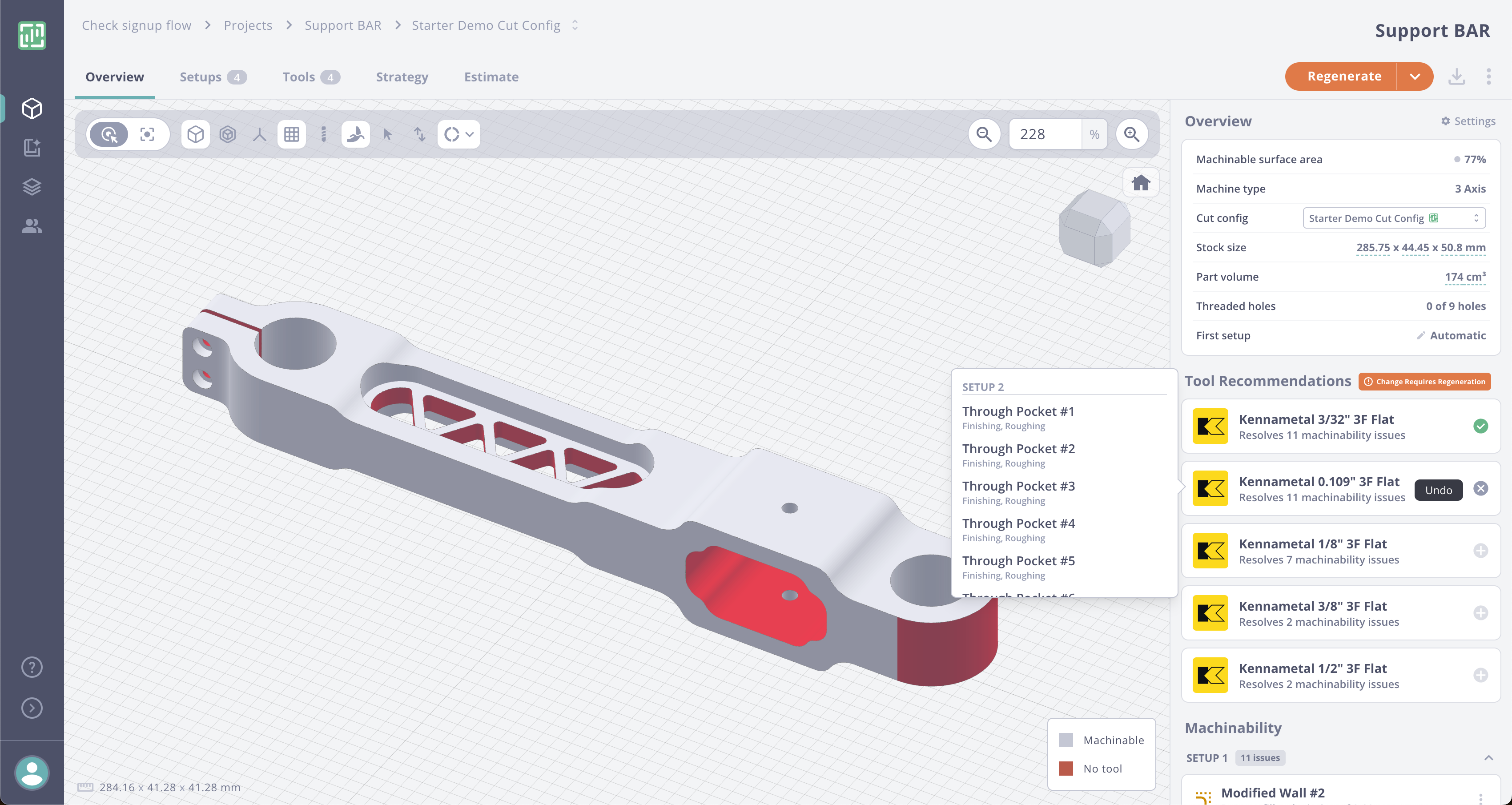

Contextual DFM

Successful shops understand which parts are a good fit for their capabilities and which ones are not. Toolpath provides contextual design-for-manufacturing feedback by generating a manufacturability report tailored to the tools you already own. It highlights potential challenges, recommends alternative tooling when needed, and helps you make faster, more confident quoting and planning decisions.

The Skills Gap Is a Myth.

The Productivity Gap Is the Real Threat.

In 1933, there were 7,000 commercial pilots in the U.S., but not enough flying jobs to match. Average pay was about $3,300 per year, which translates to roughly $77,200 today. Autopilot technology arrived and changed the game. Pilots were not replaced; instead, they became more effective and essential. Fast forward to now—there are over 400,000 commercial pilots, still not enough to meet demand, and the average salary is $211,790.

When automation is done right, it multiplies the value of skilled professionals rather than replacing them. The same transformation is happening in manufacturing.

Most machinists have the skill, but they are overwhelmed by manual quoting, constant toolpath tweaks, and repetitive setups. This is the real productivity gap. Toolpath takes care of the repetitive, time-consuming tasks so experienced machinists can focus on high-impact work: optimizing workflows, running multiple machines, improving part quality, and staying ahead in a competitive market.

Much like pilots, skilled machinists are not being replaced. They are becoming more important and more valuable than ever.

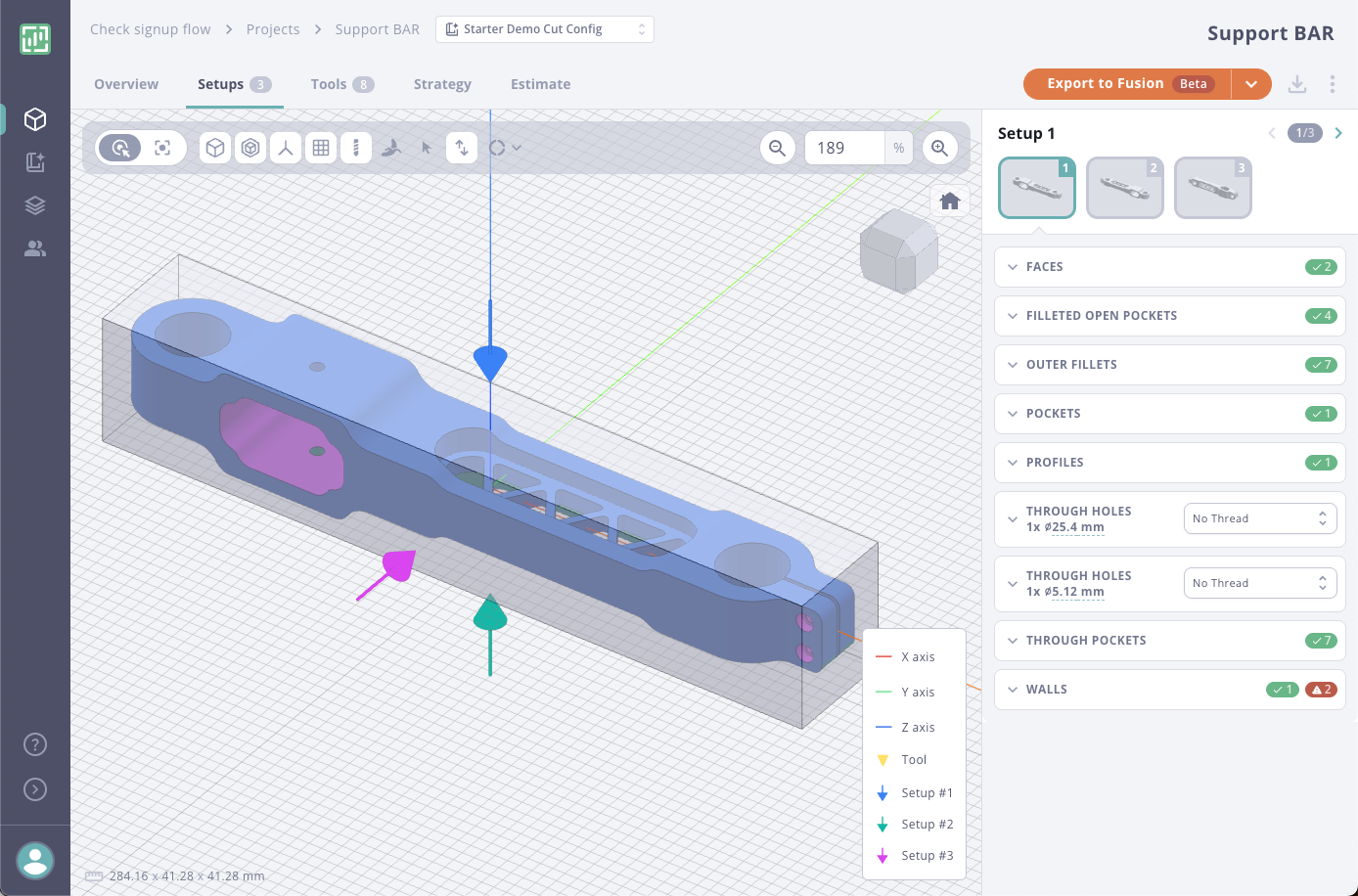

Required Setups

Every time a machinist needs to reposition a part, productivity slows down. Setups are often the most significant source of inefficiency in CNC work, and one of the most costly uses of expert time. Toolpath analyzes each part by evaluating its geometry, fixturing requirements, and tool access to determine the fewest number of setups required. Fewer setups mean less manual intervention, faster throughput, and more time for machinists to focus on high-impact work.

“If I can take the dull, dirty, and dangerous off my team’s plate and let automation handle it, I free them up to use their superpowers on the hard stuff.”

Mike Payne, Hill Manufacturing

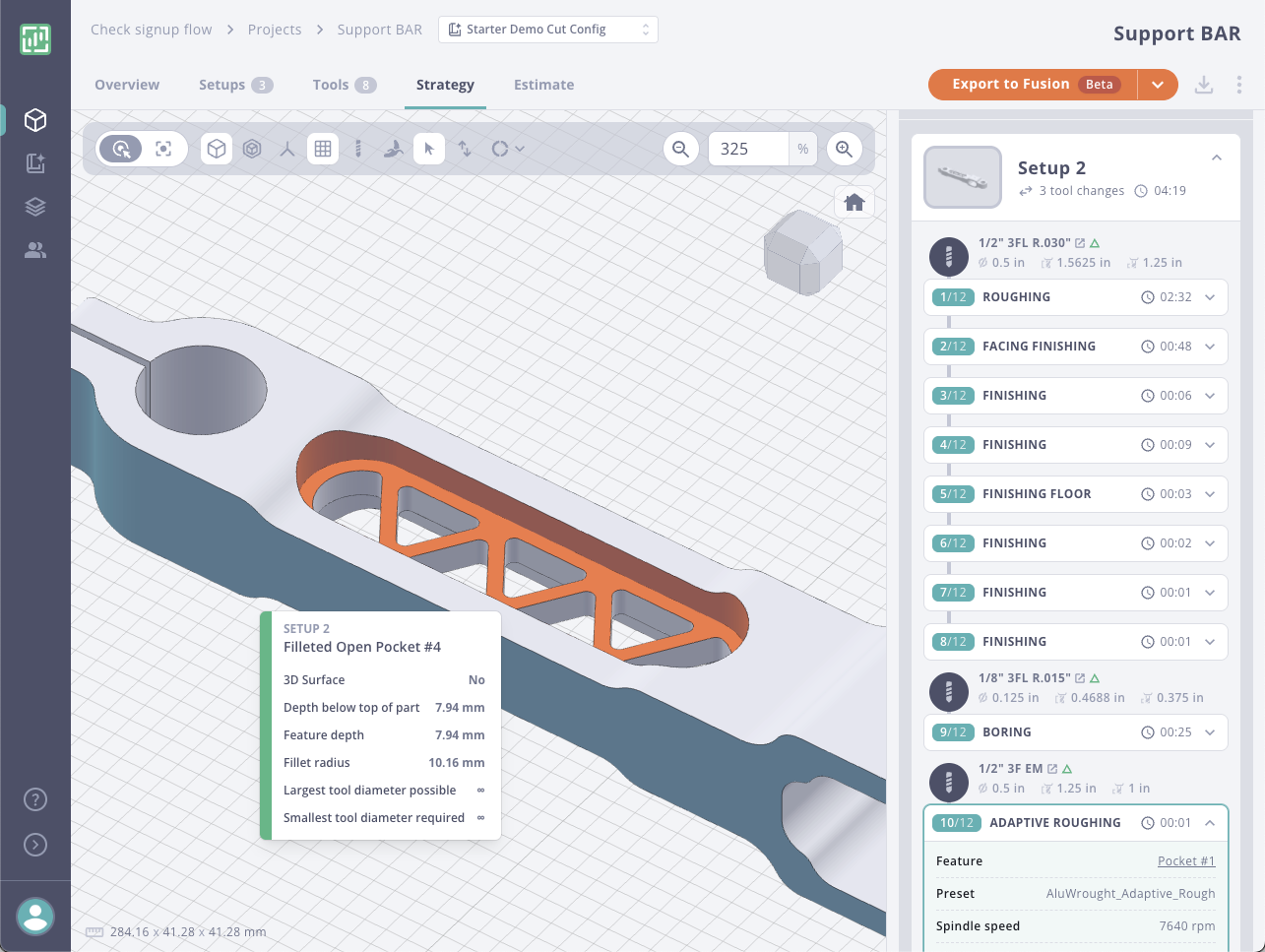

Operation Plan

Toolpath creates an operation plan the way a computer plays chess. It looks at the entire part, considers every possible approach based on the geometry, material, and tools you have, and chooses a sequence of operations that leads to the best result. By recognizing machining features and applying strategies drawn from expert knowledge, Toolpath evaluates the path ahead to optimize for efficiency, safety, and tool life. The outcome is a complete plan that reflects real shop conditions and expert-level thinking, delivered in seconds.

The New Industrial Revolution

The last time technology reshaped the labor market, it moved value from the shop floor to the front office. Physical work gave way to mental work. Engineers replaced machinists at the top of the pay scale.

But now AI is shifting that balance again. This revolution is not about going backward — it is about automating mental repetition the same way the last one automated physical labor. And as that happens, the most valuable people will be the ones with judgment and real world understanding.

Not the person who can format a drawing. The person who knows how a part holds together in the vise. The one who sees a burr before the machine stops cutting.

These professionals will not be replaced. They will be multiplied. Toolpath is here to give them leverage.

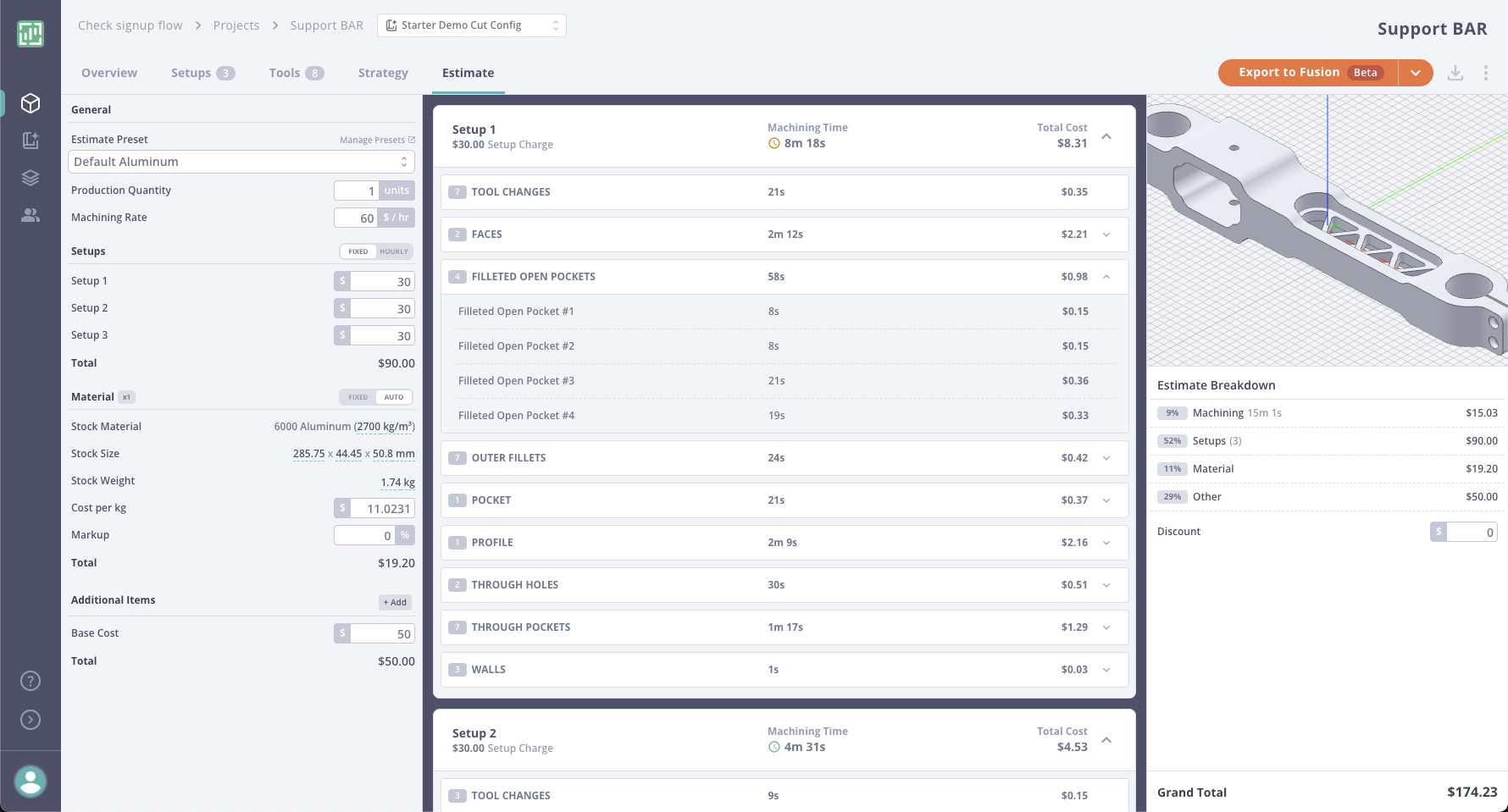

Detailed Estimate

Toolpath provides detailed time and cost estimates by simulating every operation in the plan using your machine data, tooling, and feeds and speeds. It accounts for tool changes, setup time, and cycle time to give you an accurate picture of how long the job will take and what it will cost. These estimates help you quote with confidence, prioritize jobs, and make decisions that protect both your margins and your schedule.

“The last industrial revolution automated muscle power. This one is automating brain power. As this shift happens, it is the people who understand how things actually go together, the ones with real-world context, who will become the most valuable. Toolpath exists to serve those people.”

Al Whatmough, Toolpath CEO

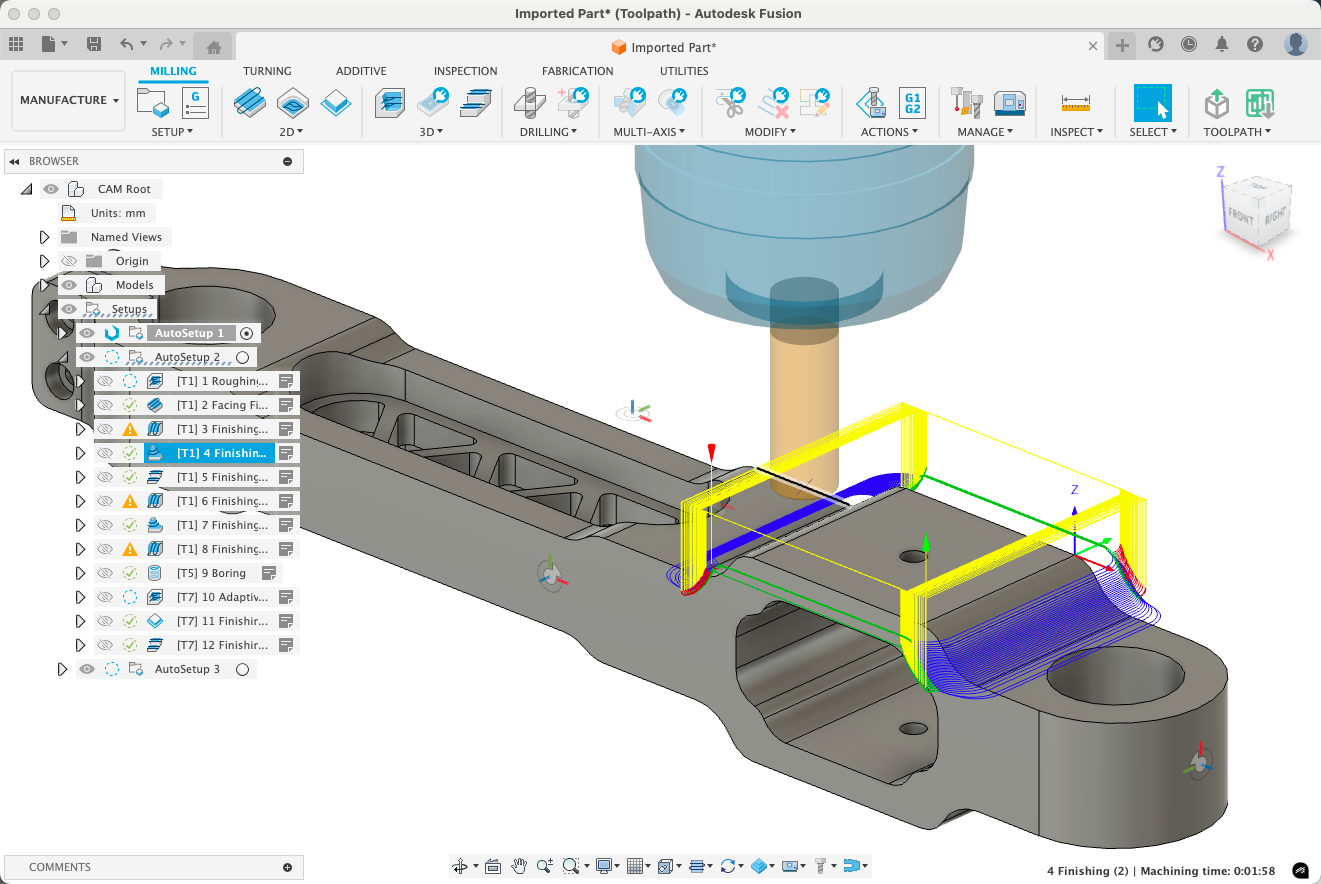

Automated Toolpaths

When you are ready to go to the machine, Toolpath exports directly to Fusion so you can review, edit, and post using the post processors you already trust. Your operation plan transfers with geometry, tools, and setups intact, making it easy to fine-tune or add shop-specific details. This workflow combines Toolpath’s speed with Fusion’s flexibility, providing the best of both worlds with zero rework between estimating and CAM.

Toolpath Increases Machinist Productivity.

We don’t replace skilled people — we remove the bottlenecks that slow them down.

If you’re quoting by hand, manually editing toolpaths, or burning time on tribal setups, Toolpath helps your team move faster.

The industry’s been talking about a skills gap for years.

But the real issue? We’re not making the most of the skill we already have.

That’s the productivity gap — and that’s what Toolpath is built to fix.

Now… full honesty:

Toolpath is a bit like a self-driving car that hasn’t figured out what to do when a plastic bag blows across the road.

It’s fast, it’s learning, and it’s already changing how modern shops operate — but it’s not perfect.

If you’re looking for polished and predictable, Toolpath might not be ready for you yet.

But if you want to be part of the future — and help shape it — we’d be honored to build it with you.

Frequently Asked Questions

Subscription

-

Can I get a refund if I'm not satisfied?

If you are not satisfied with Toolpath within the first 30 days of use, you may cancel your subscription and request a full refund.

-

Are there are setup fees?

No, Toolpath has no setup fees. You only pay for your subscription plan. Our partners may offer additional consulting services you may wish to take advantage of for a fee.

-

Can I choose between monthly or annual plans?

Yes, when you start your subscription from your Toolpath account, you can choose between annual or monthly plans.

If you currently have an early adopter or promo subscription, cancelling to switch to monthly, will void any long term benefits you may have.

-

Can I pause my subscription?

Currently, Toolpath does not offer subscription pauses, but you can cancel and resubscribe at any time.

-

What happens if I cancel my subscription?

You’ll retain access until the end of your billing cycle, but your account will deactivate afterward unless you resubscribe.

Currently, we keep your data intact, unless you ask us to delete it. In the future we may need to archive inactive accounts, but we will notify you if we end up needing to implement such a policy.

-

Do you offer volume discounts?

Yes! We have tiered volume pricing for additional users and machines. Contact us for more information.

Support and payment

-

What support is included?

All subscriptions include email, chat and phone support, as well as onboarding support with the Toolpath customer success team.

Premium support plans may be available to purchase via our regional partners.

We aim to respond to all support enquiries within 1 business day.

-

How do I get support?

You can email support@toolpath.com or submit a support ticket at any time. Please provide a descriptive subject line and detail as much of the issue as you can. Screenshots and/or screen recordings help our team to get a useful response to you as soon as possible.

-

Do I need a credit card?

You don't need a credit card to start a trial with Toolpath.

We use Stripe as our payment processing platform. In some countries we may only support Credit Card payments, however, we do offer wire / ACH transfer in some countries already.

-

What payment methods do you accept?

We try to support as many payments options as possible around the world. Typically we support major credit cards and bank to bank transfers.

We use Stripe as our payment transaction platform. Please let us know if you'd like us to support additional methods for your country.

-

How am I billed for Toolpath?

You will receive a receipt for each transaction, sent to the email you used when you started your Toolpath subscription.

Unless you cancel your subscription, you will be automatically billed at the anniversary of your annual Toolpath subscription, using the same payment method you used initially.

Contact us if you would like to change your payment method.

5112 Richmond Rd.

Bedford Heights, OH 44146