CNC Programming: It’s Just Algorithms—Or Is It?

One evening, my friend Carl looked at me and said, “It’s just algorithms, Tim.” I almost laughed. As a machinist and CNC programmer, I have spent...

1 min read

Al Whatmough

:

Updated on March 21, 2025

Al Whatmough

:

Updated on March 21, 2025

Stepping onto the shop floor at TRAK Machine Tools felt like stepping back to my roots. The smell of coolant, chips in my shoes, and the hum of CNC machines—it was the kind of hands-on day that reminds me why I got into machining in the first place.

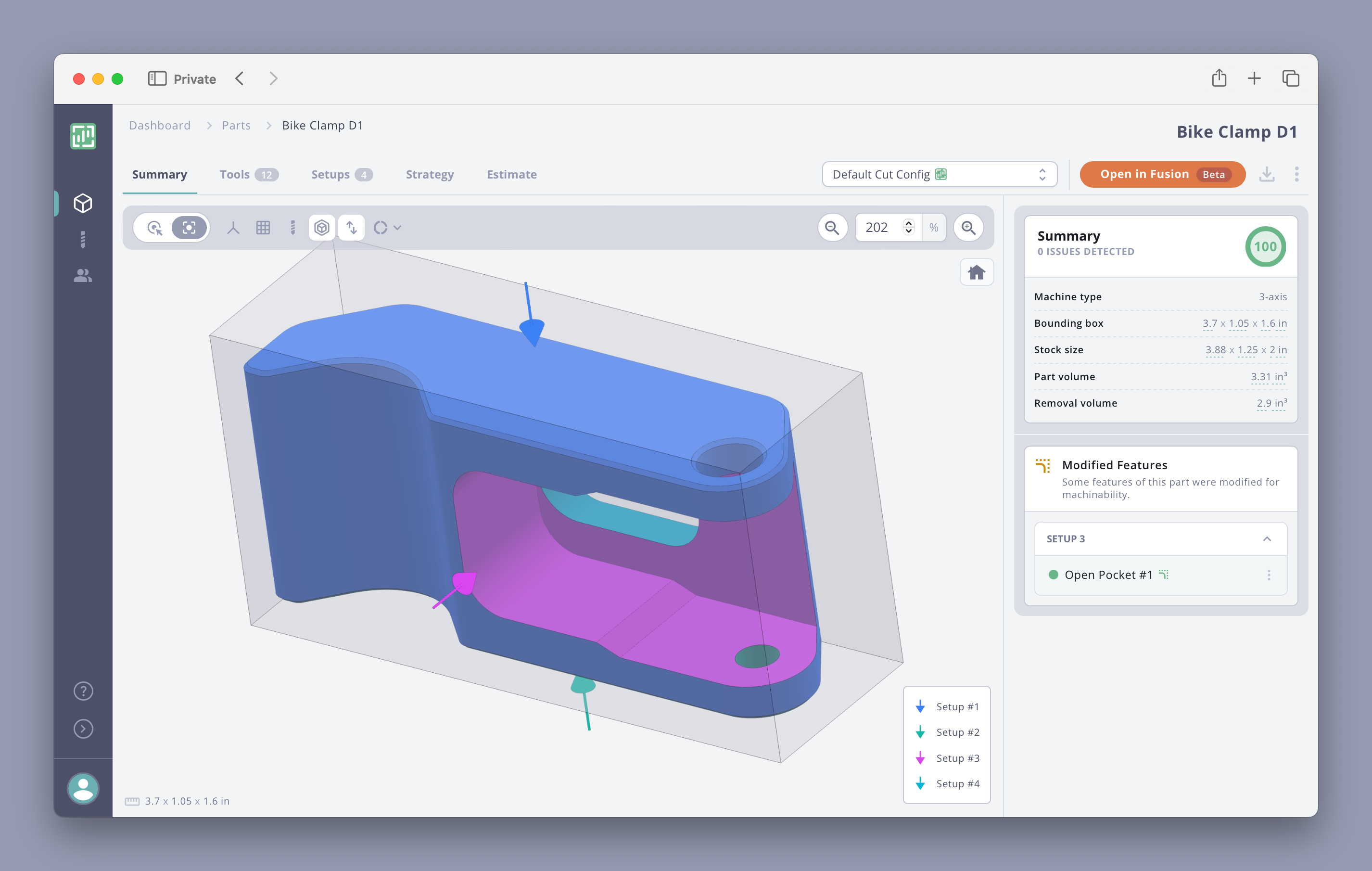

But this was more than just a trip down memory lane. It was about finding the hurdles in our workflow at Toolpath, validating Toolpath Automation, and reimagining the connection between software and machine.

One of the most valuable moments was my time with TRAK’s master machinists—people who have been making parts for almost as long as I have been alive. I had them look at parts in Toolpath for the first time and share how they identify machining issues. Their feedback was clear: we need to make the onboarding process more streamlined and help them add data like tools and tolerance feedback on the fly.

When it was my turn to machine a part, they handed me a cart of tools and said, “Use whatever you need.” That moment made it real. Machinists do not work with generic tool libraries. They use the tools they have. If we want Toolpath to work, it needs to help machinists feed it with the tools in their shop.

I also spent time with TRAK CEO Steve. He is not one of the master machinists, but that did not stop him from giving me a refresher course on the TRAK control. It was a great reminder that even leadership at TRAK stays hands-on with their technology, making sure it remains accessible and powerful for machinists at every skill level.

The ProtoTRAK RMX interface reminded me of something crucial: automation should empower the machinist, not replace them. When I was learning CNC, flip-out handwheels made automation feel intuitive. We need to do the same for Toolpath—bringing new levels of automation while keeping the machinist in control.

The Big Takeaway

This visit reinforced that Industry 4.0, digital twins, and automation are not just buzzwords. They are solvable problems—but only if we keep the machinist at the center. Partnering with TRAK, the company that first brought CNC machining to the shop floor, feels like the right move.

We are not just building software. We are redefining how machinists and machines work together. And after a day covered in coolant, I am more convinced than ever that we can make it happen.

One evening, my friend Carl looked at me and said, “It’s just algorithms, Tim.” I almost laughed. As a machinist and CNC programmer, I have spent...

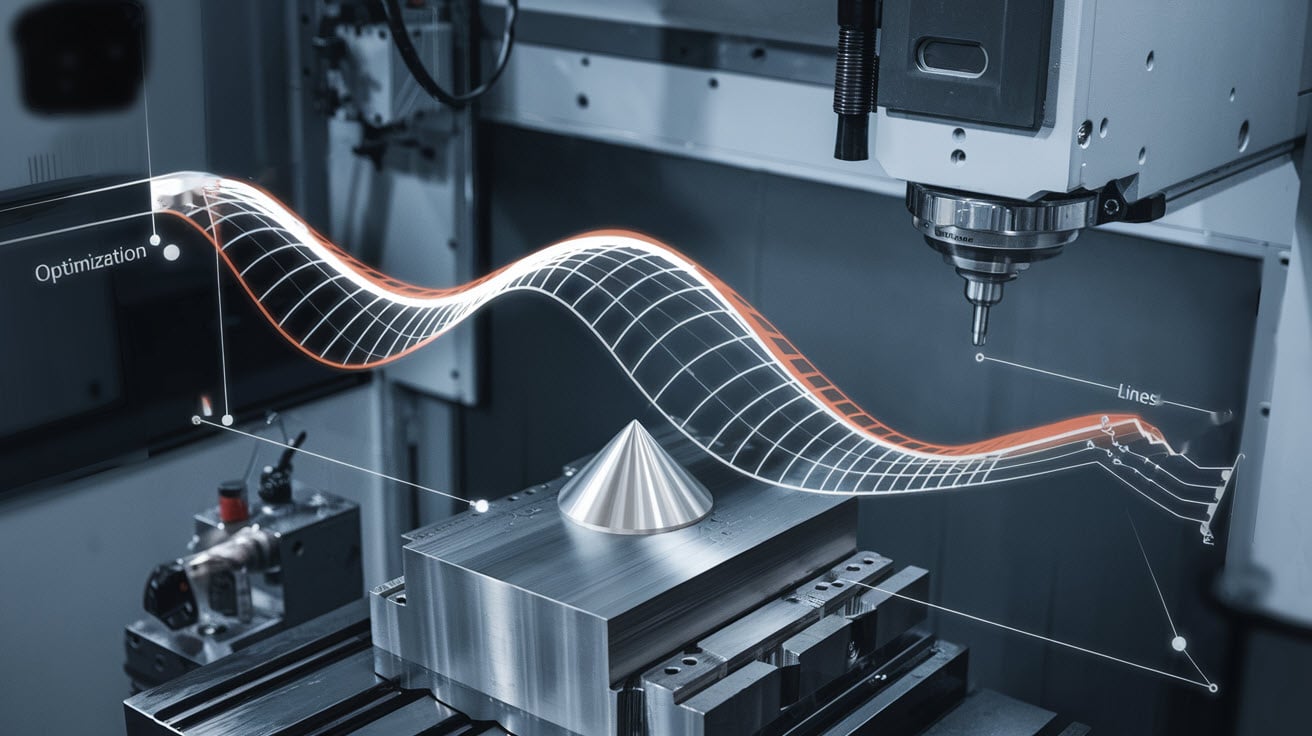

Imagine spending hours programming, setting up, and machining a part, only to scrap it because your roughing toolpaths gouged the final geometry...

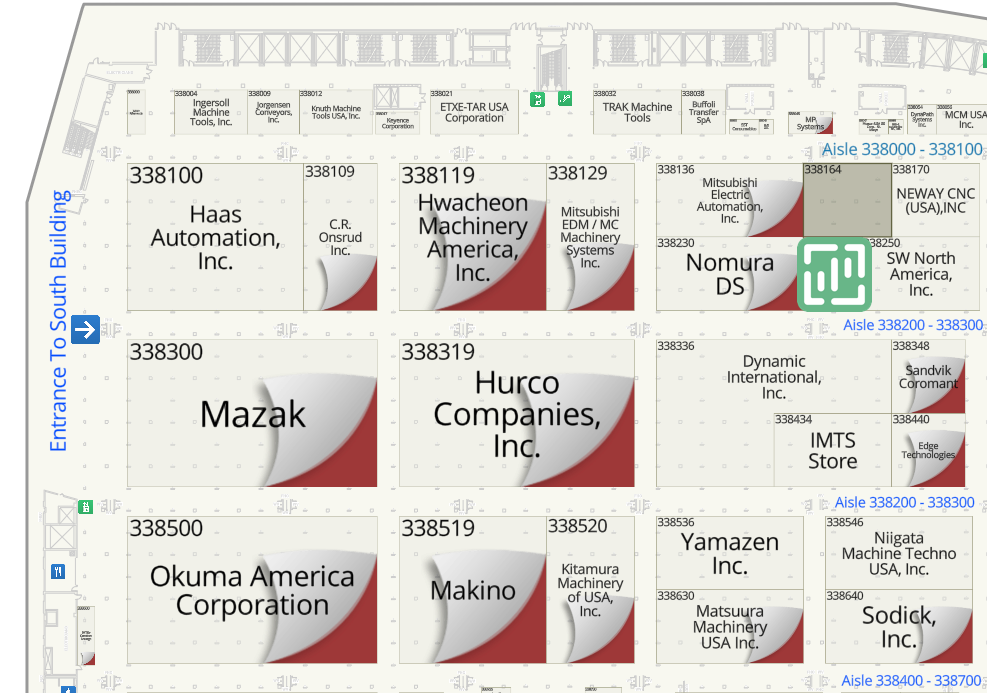

Bedford Heights, Ohio - July 22, 2024 – Toolpath is excited to announce its plans to exhibit at the International Manufacturing Technology Show...

At Toolpath, we believe that to build an effective AI CAM Automation platform, we need firsthand experience with CNC machining. We needed to...