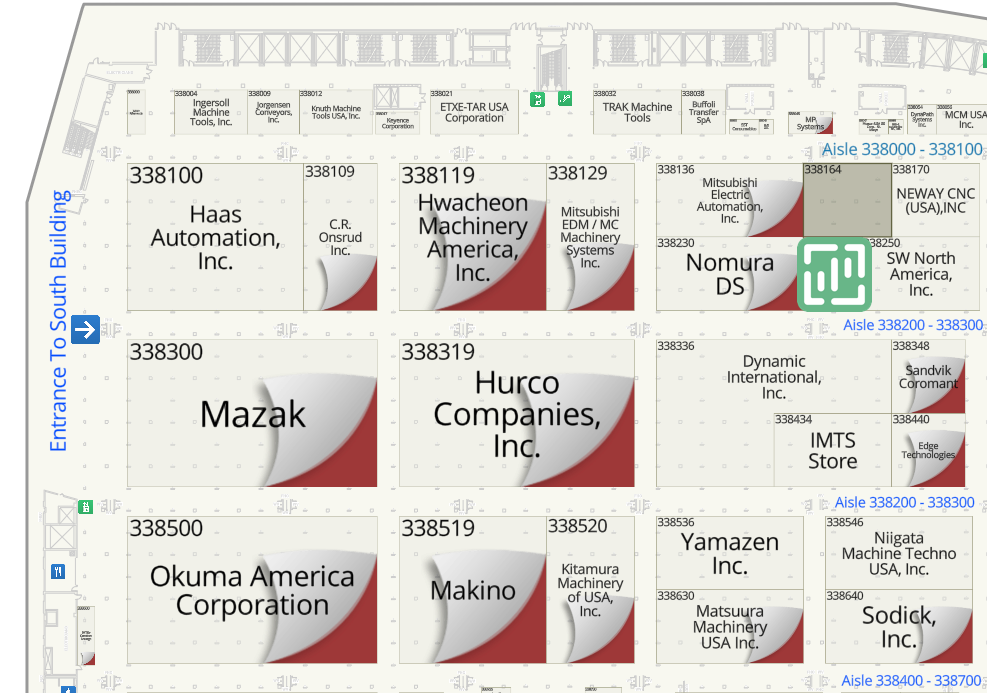

Toolpath to exhibit at IMTS 2024 (Booth 338248)

Bedford Heights, Ohio - July 22, 2024 – Toolpath is excited to announce its plans to exhibit at the International Manufacturing Technology Show...

1 min read

Justin Gray, Ph.D.

:

Updated on August 10, 2024

Justin Gray, Ph.D.

:

Updated on August 10, 2024

At Toolpath, we believe that to build an effective AI CAM Automation platform, we need firsthand experience with CNC machining. We needed to understand what it really felt like to stand in front of a machine and press cycle-start ... needing to get a good part out of it.

This is why we set up a small R&D machine shop, not to become a full scale job shop but to experience high-mix, low-volume work first hand. To spend time working as machinists making parts, and understanding where our technology fit into the realities of that kind of manufacturing.

Our first machine, a Tormach 770 MX, was set up in Andy's garage in 2021. The second, a Syil X7 with LNC 6800 control, followed in my garage in May 2022. Both machines are still in use at Toolpath, helping us test our software.

Setting up the Syil was memorable. I prepped the garage myself, running air lines and electrical from an existing car charger, and added extra LED lighting for better visibility.

On these machines, we've learned invaluable lessons, tapping in tools to minimize runout, chasing flatness callouts, and standing for hours swapping parts late into the night to hit a shipping deadline. Before tackling the finer points of CAM automation, we had to handle the realities of machining: building efficient work areas, managing tools, and storing equipment.

One of my mistakes was placing tool storage too far from my workbench, which often meant I spent more time setting up tools than running parts. This is a big reason why Toolpath's AI understands the need for core tools ... because I didn't want to set up new tools if I didn't have to!

We've since moved to a dedicated shop in Bedford Heights, Ohio, with more space and power for larger machines like our Brother Speedio S500X2. We kept the Syil for R&D and added a 4th axis to start exploring multi-axis machining. I'll give a shop tour another time.

But while I was running some parts today, and had to spend a while repairing something in my wireless probe, I realized how vital it is to take the process all the way to the machine, load stock, and push cycle-start. AI CAM Automation is a critical piece of tech we need to improve our manufacturing capacity, but you can't build it in isolation.

It has to work in conjunction with the real world realities of making parts --- like relying on functioning probes and zero point workholding to keep workflows efficient.

Bedford Heights, Ohio - July 22, 2024 – Toolpath is excited to announce its plans to exhibit at the International Manufacturing Technology Show...

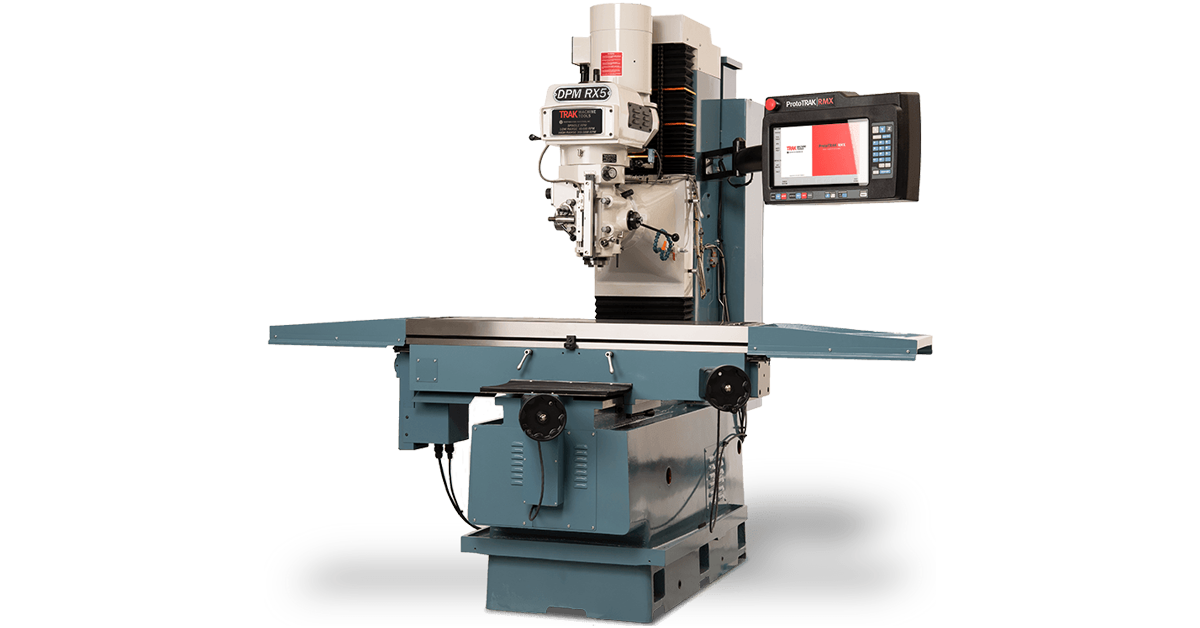

Toolpath and TRAK Machine Tools announce a partnership to bring AI-powered solutions to machine shops across the US and Canada. Toolpath (Toolpath...

Hey Toolpath Community! September was a busy month with IMTS (see our recap here), and the Toolpath Team has been working hard to bring you some...

Toolpath Partners with DSI to expand sales support and meet increasing demand across the U.S. and Canada

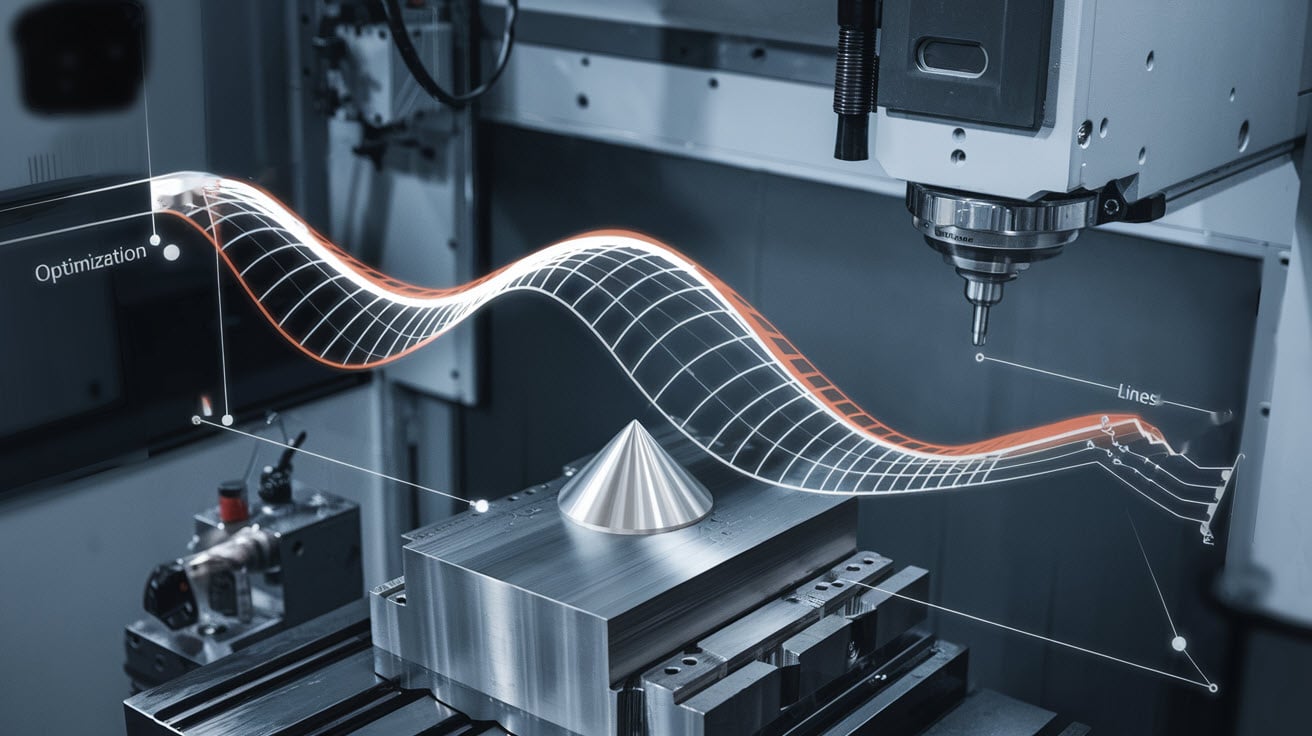

Imagine spending hours programming, setting up, and machining a part, only to scrap it because your roughing toolpaths gouged the final geometry...