CEO Playdate at TRAK: Machining, Learning, and the Future of Automation

Stepping onto the shop floor at TRAK Machine Tools felt like stepping back to my roots. The smell of coolant, chips in my shoes, and the hum of CNC...

On a visit to Proteum Machining, I had the chance to dive into their processes and Dylan was brave enough to let me go full machinist geek and critique his shop. We explored every detail in episode 240 of Within Tolerance, but one of the standout discussions for me was about CNC macros and how they can transform efficiency in machining.

While helping with the kinematic calibration routines on a Hermle C250, I saw several manual steps where Dylan had to call macros from the MDI screen. Not every CNC control operates this way, but many do. Popular systems like Fanuc, Heidenhain, and even Syil’s LNC control use MDI for quick macro access.

Check out this shot of the MDI screen on the Toolpath Syil X7. G65 is the call to a sub-program, and believe it or not, I can name programs with actual words on this control. Revolutionary, right?

He kept these commands handy in his MDI list, calling them one by one. Between steps, he managed manual tasks like cleaning tools, inspecting the probe tip, and installing the gauge ball.

I suggested combining these steps into one macro to save time and avoid hovering near the machine for 10 minutes. Naturally, this led to a debate: Is it worth the effort to make a macro more automated?

My answer is always yes. Humans make terrible robots because we are just not designed for repetitive tasks. Automation does not just save time; it also reduces mental fatigue and minimizes errors.

Automating routines like kinematics calibration means you are more likely to run them regularly. Plus, encoding processes into macros eliminates the need for documentation. It is a win on multiple fronts.

Macro programming is not everyone’s forte. CNC controls like Brother, Fanuc, Syil, and Heidenhain each have quirks, making cross-platform programming challenging for many machinists

A good macro is not just written; it is planned. Here are some tips to streamline your workflow:

Standardize artifact locations: Use a zero-point system or mark spots for gauge blocks.

The payoff is a three-step routine that becomes a single macro call, saving time and mental energy.

On the Syil X7, I developed open-source macros to simplify my probe and toolsetter calibration workflows. The Probe calibration macro has two modes:

On the Syil X7, I developed open-source macros to simplify my probe and toolsetter calibration workflows. The Probe calibration macro has two modes:

Manually jog to the starting location once, and it saves the position to a WCS.

Calls the saved position automatically, no jogging required.

I currently use a marked spot on the HWR plate for reference, but even that is not ideal. A fixed gauging plate with some studs would ensure perfect repeatability every time.

Every incremental automation improvement gets you closer to a fully automated shop. Imagine a robot changing pallets, running the warm-up routine, and performing calibration, all without human intervention. That is the dream, and every small step toward it is worth the effort.

Macros are not just about efficiency. They unlock the potential for greater automation. Whether it is reducing manual intervention or paving the way for robotic integration, programming smarter is the future of machining.

Stepping onto the shop floor at TRAK Machine Tools felt like stepping back to my roots. The smell of coolant, chips in my shoes, and the hum of CNC...

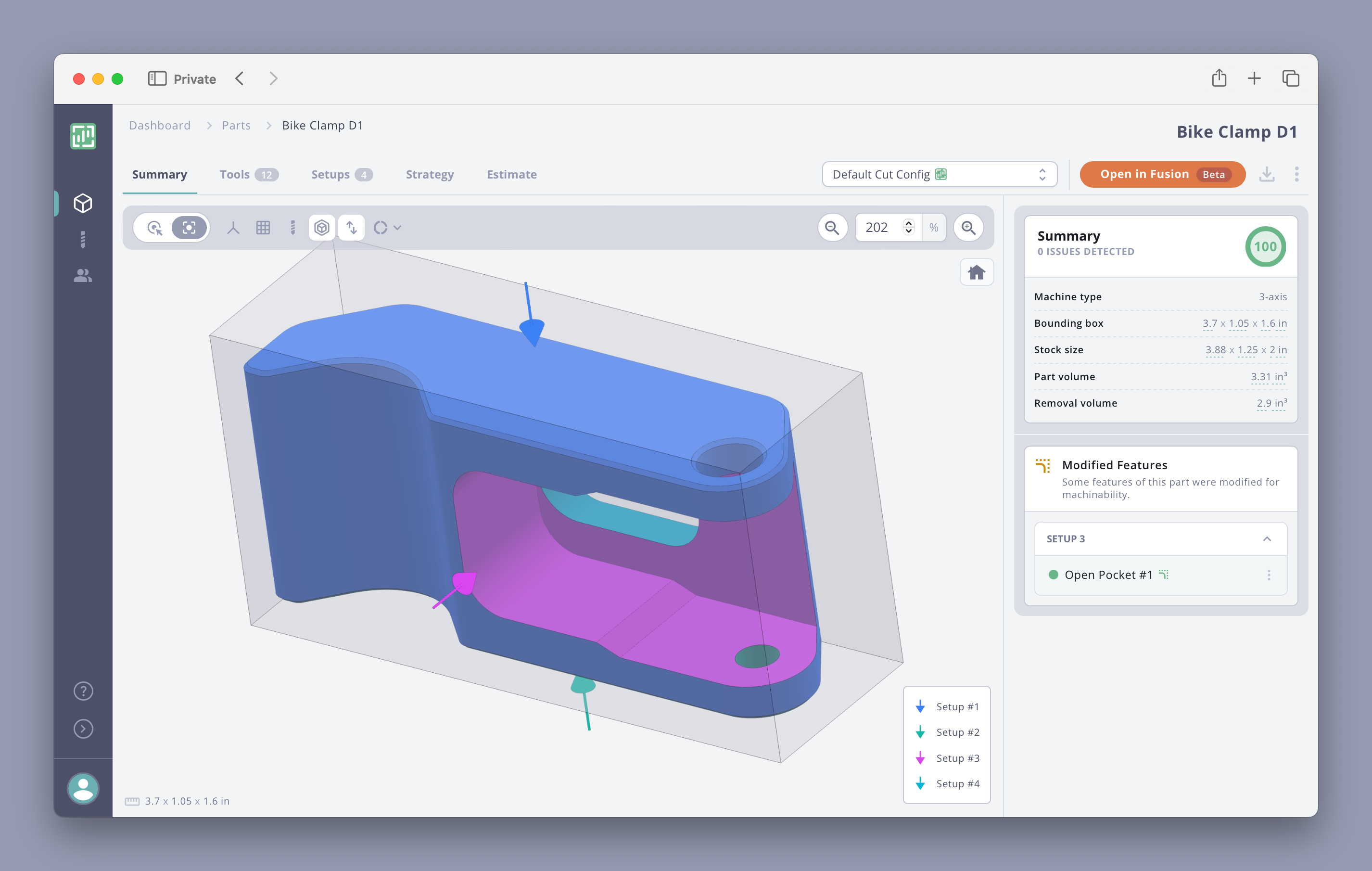

At Toolpath, we believe that to build an effective AI CAM Automation platform, we need firsthand experience with CNC machining. We needed to...

ModuleWorks and Toolpath Announce Technology Partnership Driving Cloud-Based CAM AutomationBedford Heights, Ohio - September 9, 2024 – ModuleWorks, a...

One evening, my friend Carl looked at me and said, “It’s just algorithms, Tim.” I almost laughed. As a machinist and CNC programmer, I have spent...

Part two of the MakingChips conversation with Mike and Nick is now live — this one goes deep into Toolpath and the thinking behind how it helps shops...