We've got some exciting new features and updates to share in our May product release. Enjoy!

New Features

Tool Recommendation Engine

Magic Uploads for Tool Libraries

Banana for Scale

App Improvements

Cut Configs Redesign

Part Overview Facelift

New Features

Tool Recommendation Engine

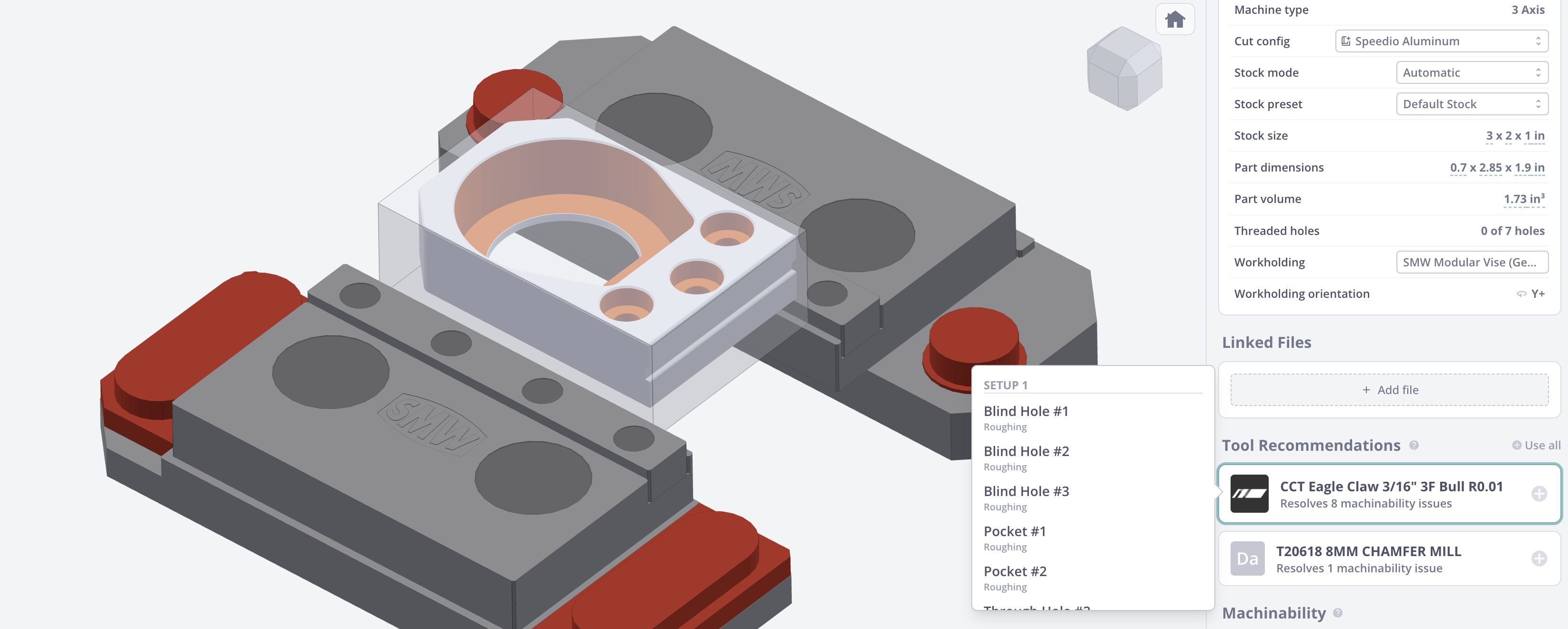

We’re excited to release the Tool Recommendation Engine. This feature is truly game-changing when it comes to finding the right tool for uncommon geometry, and also works great as your go-to source if you’re just starting with a small tool library.

When you upload a part to Toolpath, the engine can now search through a catalog of thousands of tools to find the best match for any unmachinable geometry. It analyzes key parameters — like diameter, reach, and corner radius — to identify the optimal tool, then determines the most efficient way to resolve as many features as possible using that tool.

At launch, we’ve included libraries from Kennametal, Haas Tooling, and Harvey Tool for every Toolpath user. These libraries come already complete with reliable starter feeds and speeds, generated by PreTool.

To enable recommendations, navigate to your Cut Config, select the Recommendations tab, and enable libraries from your go-to vendors.

To use tool recommendations in a program:

-

Click a recommended tool in the right hand side inspector on the overview tab to highlight the associated features.

-

Press the “+” icon to import a tool to the current part

-

Click the Regenerate button (orange) once you have made all desired changes

Magic Uploads for Tool Libraries

When you upload a tool library that doesn’t contain presets, Toolpath now automatically calls on PreTool to populate any missing presets so the tools can be used in programs and estimates immediately, without any manual applying of presets.

If you want to edit these values later, you can still edit in PreTool or Fusion as you normally would - magic uploads won’t touch any presets you’ve modified yourself.

Banana for Scale is Here to Stay

We originally introduced the “Banana for Scale” button in the 3D viewer as an April Fool’s Day gag, but it turned out to be a beloved way to get a sense of a part’s scale in Toolpath, so we’re keeping it permanently.

App Improvements

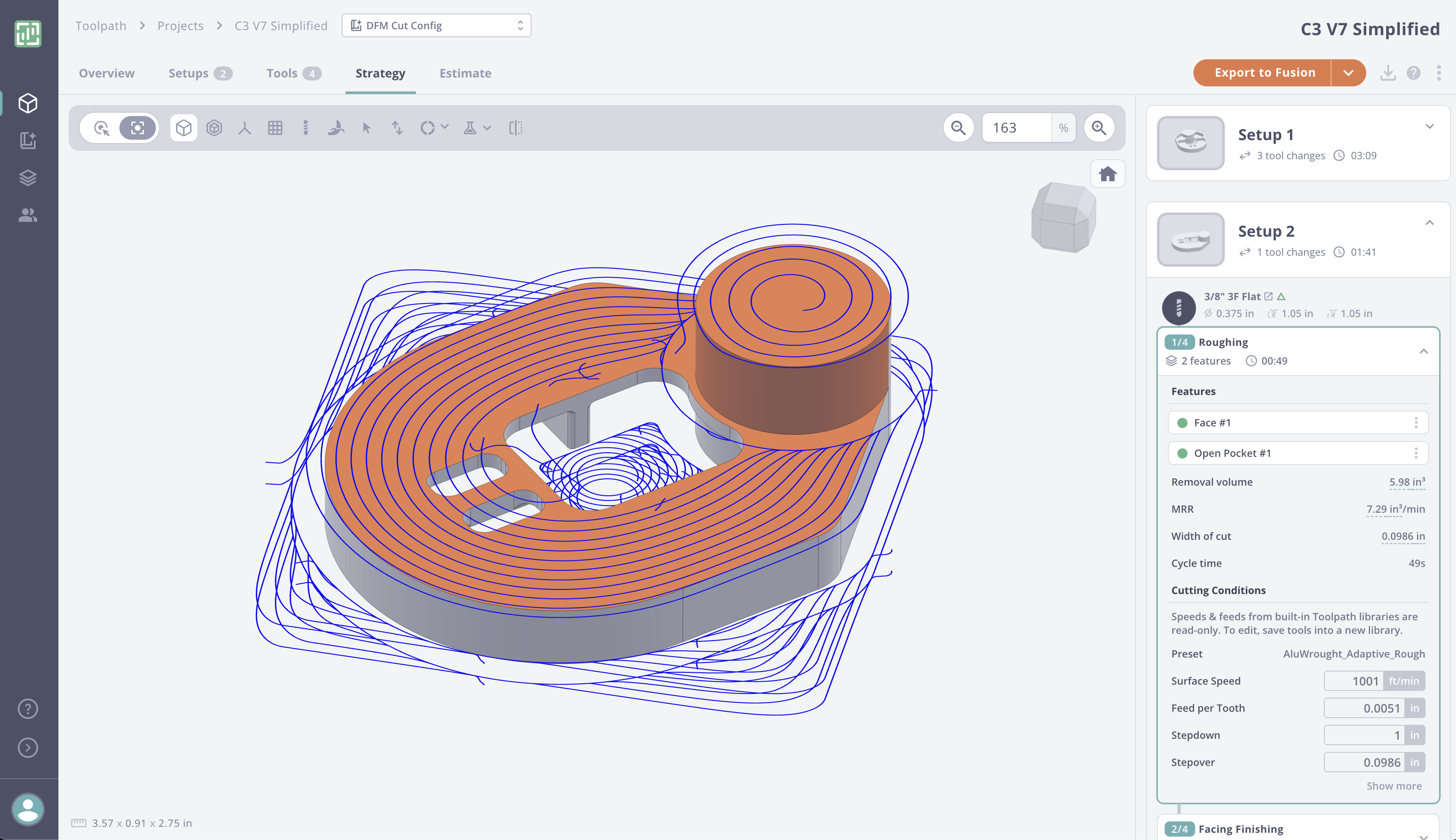

Cut Configs Redesign

We’ve revamped the Cut Configs editor to make it easier to use and faster to navigate.

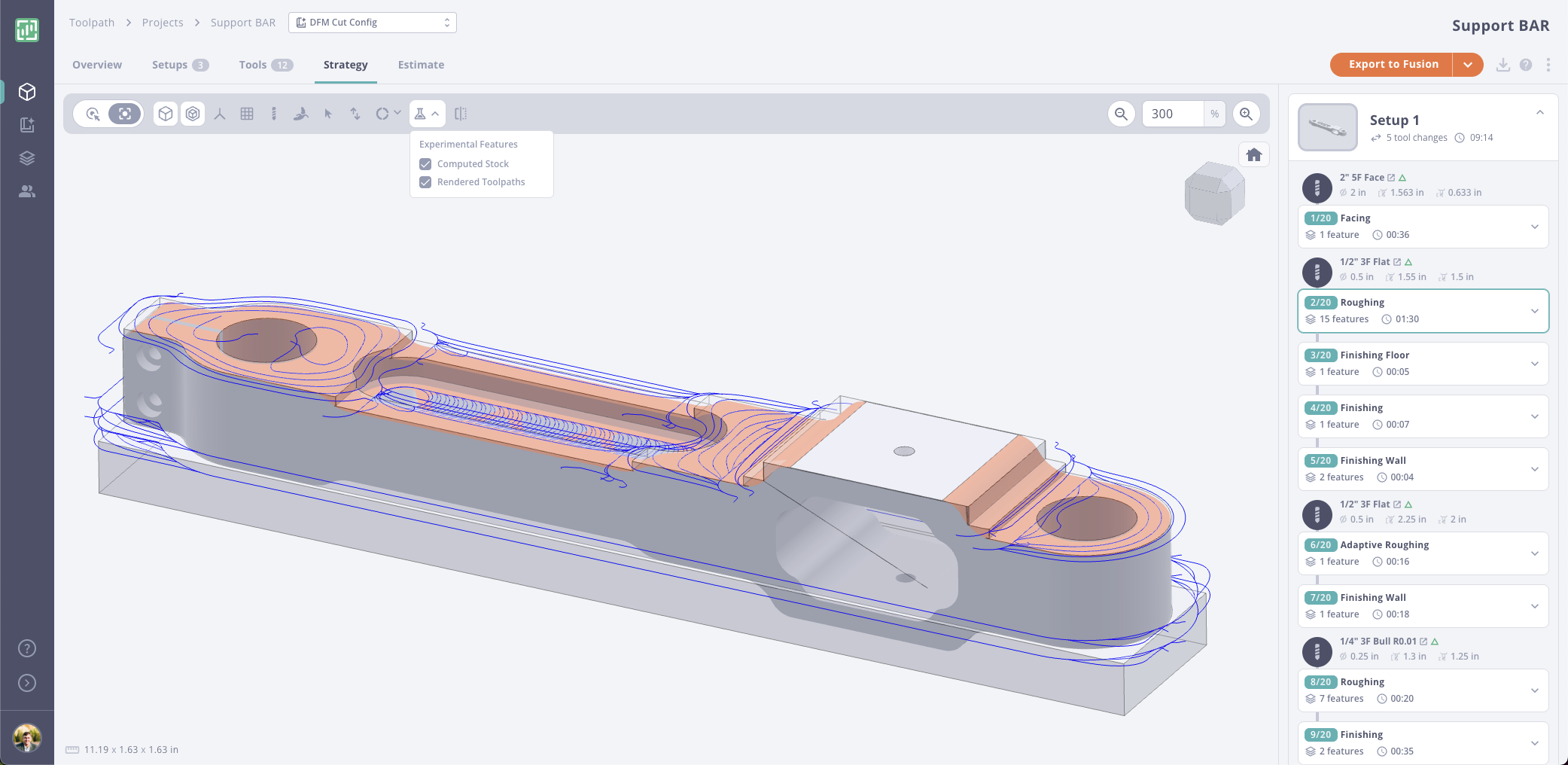

Overview Tab

On the overview tab, you define how you want Toolpath to program your parts in this cut config. This includes things like stock to leave and smoothing tolerance, as well as defining engine engine behaviors, like geometry deviations and bullnose substitution.

💡About Geometry Deviations

Ignore Deviations Under This is helpful when a model has imperceivable modeling errors -Toolpath will automatically correct for model deviations under an amount you set.

Suggest Radius Deviations Up To This setting allows Toolpath to select a tool of a greater size than the modeled radius, up to a certain amount. This is helpful in cases where a radius smaller than any available tool is present, but a larger machined radius is acceptable.

💡 About Bullnose Substitution Enabling Bullnose Substitution tells the Toolpath engine that it may treat square floor edges as if they have a floor radius, and choose a corresponding bullnose tool for roughing. Note: When a floor radius is modeled, Toolpath will make no change and instead respect the radius as defined in the model.

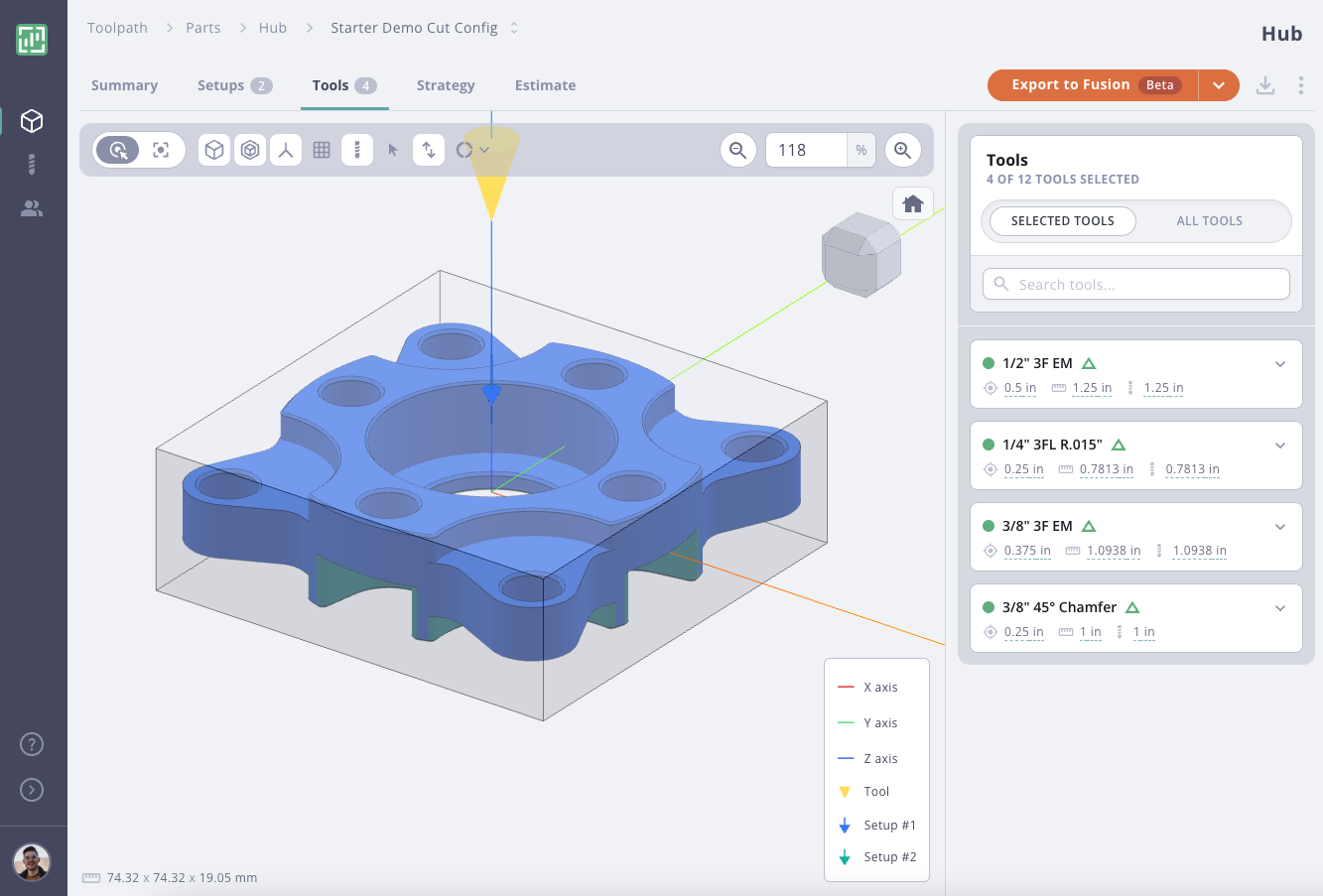

Tool Libraries Tab

On this tab, select the libraries you want Toolpath to primarily use to program your parts. In this example, we’ve set the mill’s carousel tools to preferred priority.

New: You can now see a full searchable list of tools enabled in this cut config. This list is an aggregate of every enabled library in the cut config.

Recommendations Tab

This tab defines what tools the Tool Recommendation Engine has access to. In this example, we’ve enabled the built-in Harvey Tool and Kennametal libraries, plus a few generic drill and tap libraries. If there are features not satisfied by your main library, Toolpath will suggest tools from these.

Don’t be afraid to enable a large amount of tools in this tab. A range of 500-3000 tools is a good starting point to make sure the Recommendation Engine can find the optimal tool.

In the example above, we are machining aluminum, so we’ve selected 3 flute tools for Kennametal and Harvey Tool.

Roles Tab

The roles tab auto-populates with all your tools. If anything is missing, it will now display the “unassigned” flag so you know you may want to assign a tool.

All of the pre-baked vendor tools already have roles assigned, so as long as auto-assign is enabled, there is no need to adjust.

QOL Improvement: “Make Default” Button

Make a cut config your user default by clicking the “make default” button.

Part Overview Facelift

We’ve updated the part overview tab with a more streamlined look. Our intent with this new look is to greatly simplify the page and give you faster access to the information that matters. If the part is “good to go” - you just have a nice green check. Otherwise, your warnings will be there to resolve, neatly categorized.

QOL Updates

- UI facelift on libraries lists (Tools, Cut Configs, Stock Settings, & Estimate Presets)

- Deviation settings are now defined in the Cut Config, rather than by a user preference

- “Tool Compaction” is now called “Tooling Capacity”

Pete Oxenham

Pete Oxenham

.jpg)