Best Toolpath Strategies to Machine Complex Parts Faster

At Toolpath, we’re always exploring how tooling strategies, programming workflows, and machine setups impact the bottom line. A few years back, I...

2 min read

Tim Paul

:

Updated on September 19, 2025

If you’ve worked in or around CNC machine shops, you’ve probably heard: “We just can’t find good people.”

Yes, skilled machinists, estimators, and programmers are harder to find. But the bigger problem?

Broken, outdated workflows that waste time and stall output.

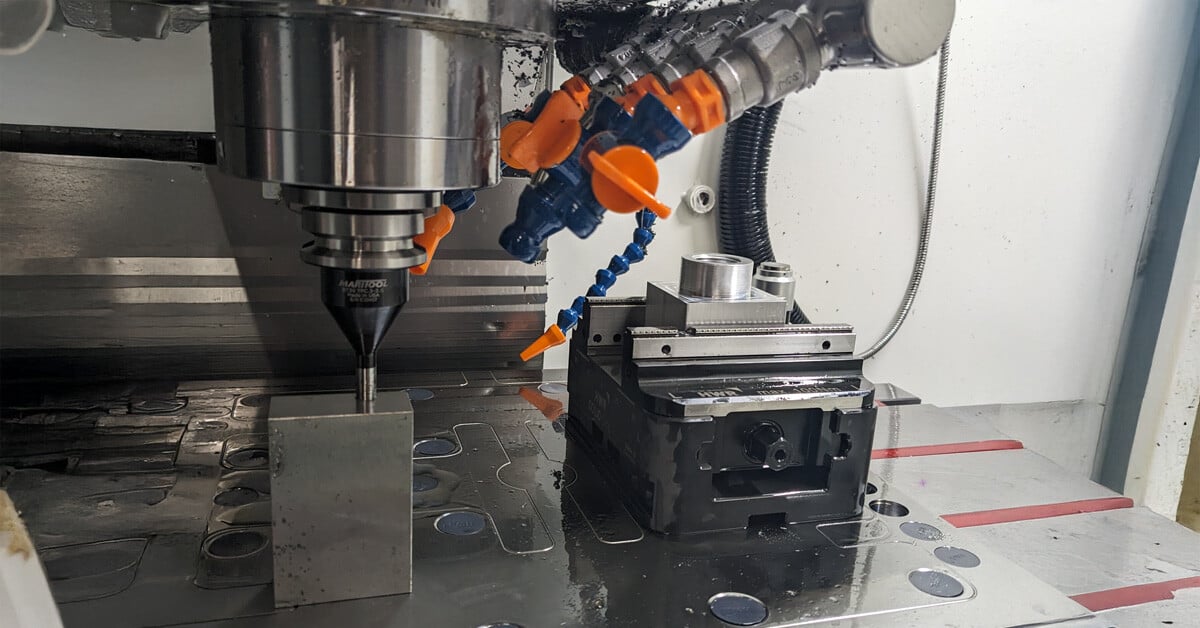

The CNC productivity gap happens when talented machinists spend their days battling spreadsheets, mouse clicks, and messy documentation instead of cutting chips.

Even the best people struggle when workflows are clogged with waste. For many shops, that looks like:

Clicking through thousands of repetitive CAM programming steps

Re-entering data into quoting spreadsheets

Searching for tribal knowledge or lost documentation

Fighting with non-standardized workholding setups

Digging through tool libraries and disorganized files

The issue isn’t the talent. It’s the system they’re stuck in.

Imagine landing that dream hire, a unicorn programmer. What happens next?

They spend half their time copying toolpaths, hunting for missing data, and rebuilding old setups. It’s a quick way to burn out great people.

Talent doesn’t scale unless systems support it.

The future of CNC isn’t just about finding more machinists. It’s about giving your current team better tools.

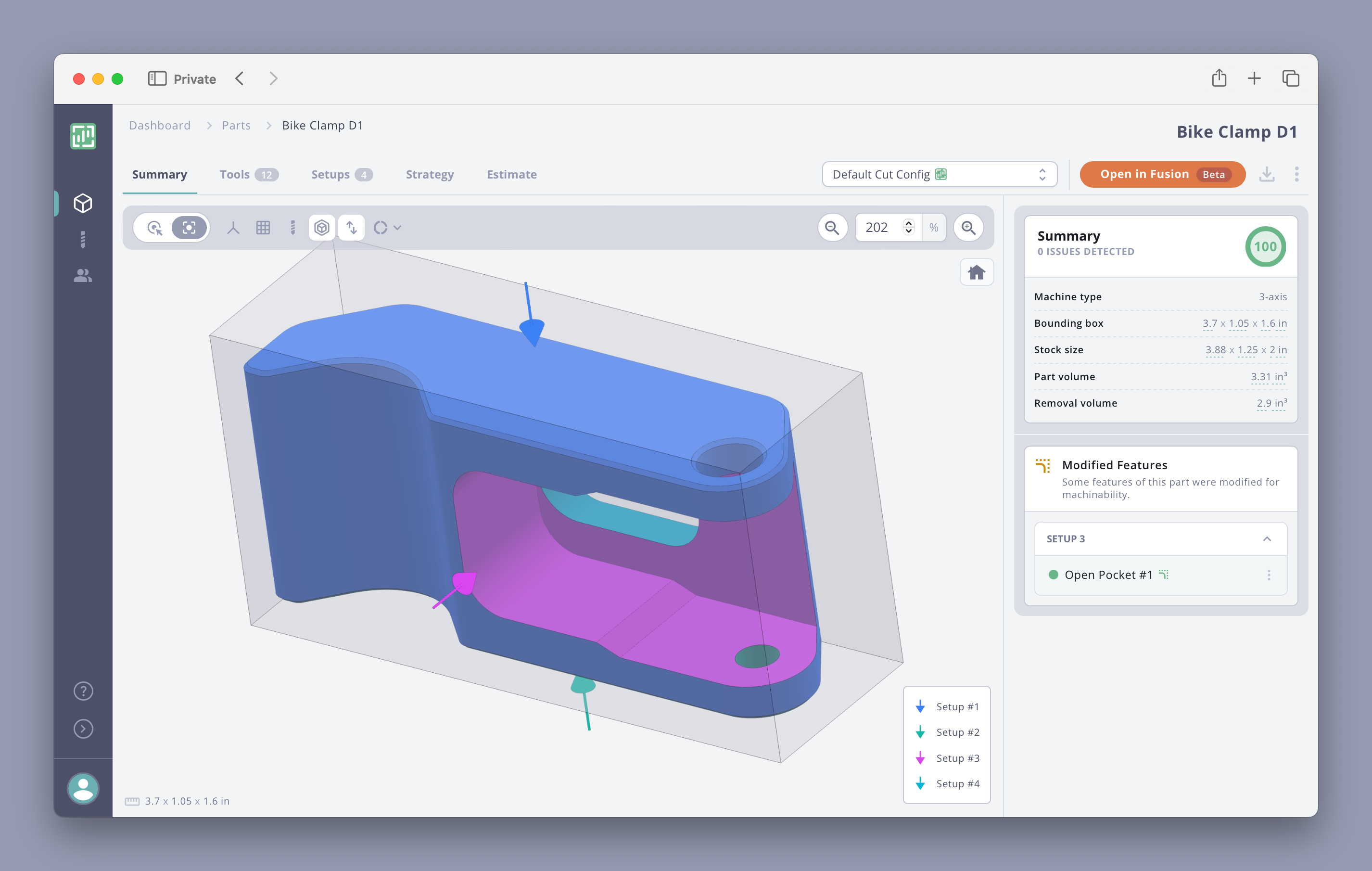

At Toolpath, we built our platform to solve the productivity gap head-on.

Generate accurate quotes in minutes, not days

Automate repetitive CAM workflows with smarter decision-making

Standardize tool libraries and setup documentation across jobs

Every mouse click is a decision. Toolpath helps redirect that effort toward solving complex problems and scaling your shop’s output.

Change takes activation energy, but even small gains compound over time.

If your shop gets just 1% more efficient each week (faster quotes, fewer clicks, better documentation), the year-end impact is transformative.

Productivity keeps your machines cutting, your team energized, and your customers coming back.

Every shop owner wants the same thing: to do great work, hit deadlines, and protect their team from burnout. Recruitment is important, but the leverage point is modernizing workflows today.

Toolpath helps CNC shops scale productivity through AI-powered quoting, CAM automation, and connected workflows.

The biggest bottleneck in CNC machine shops isn’t a shortage of skilled people—it’s a productivity gap. Too often, machinists and programmers spend more time on low-value tasks like data entry, repetitive CAM work, and searching through disorganized files than they do on actual machining. These inefficiencies slow down quoting, setup, and job prep, creating delays that ripple across the shop.

What really holds shops back is the lack of streamlined, standardized processes. Without consistent tool libraries, clear documentation, and automation to eliminate repetitive steps, valuable time and expertise get wasted. Addressing these productivity issues—especially in the early stages of quoting and setup—unlocks far greater throughput than simply hiring more people.

At Toolpath, we’re always exploring how tooling strategies, programming workflows, and machine setups impact the bottom line. A few years back, I...

One evening, my friend Carl looked at me and said, “It’s just algorithms, Tim.” I almost laughed. As a machinist and CNC programmer, I have spent...

On a visit to Proteum Machining, I had the chance to dive into their processes and Dylan was brave enough to let me go full machinist geek and...

Toolpath Closes Strategic Investment Round, Led by Kennametal, to Revolutionize CNC Machining and Manufacturing Using AI ModuleWorks also invests,...

Well, I have officially started my new role as CEO of Toolpath (toolpath.com). I will always look back at my time at Autodesk with gratitude and a...