How is CNC Used in Automation?

CNC (Computer Numerical Control) technology has become the backbone of modern manufacturing automation. CNC machines have revolutionized the way...

4 min read

![]() Toolpath

:

February 3, 2025

Toolpath

:

February 3, 2025

In the world of manufacturing, efficiency is the name of the game. The more efficiently you can produce high-quality parts, the more competitive your business becomes. That's where CNC (Computer Numerical Control) technology comes in. CNC machines have revolutionized the manufacturing industry, enabling companies to produce parts faster, more accurately, and more consistently than ever before. This post will explore how CNC technology impacts manufacturing efficiency and what that means for your business.

Before we discuss CNC's efficiency benefits, let's define CNC technology. At its core, CNC is a manufacturing process in which a pre-prepared program, called g-code, dictates the movement of factory tools and machinery.

Think of it like this: In traditional machining, a skilled operator manually controls the movement of the cutting tool, making adjustments based on their experience and judgment. With CNC, the computer is in control. It follows a pre-determined set of instructions (the CNC/ G-Code program) to guide the machine tool through manufacturing the part.

This computer control brings several key advantages:

Now that we have a basic understanding of CNC technology let's look at how it impacts manufacturing efficiency.

One of the most significant ways CNC technology boosts manufacturing efficiency is by drastically reducing production times. With CNC, once a program is created, the machine can execute it at high speeds and with minimal downtime between cycles.

Let's consider an example. Say you need to produce a batch of 100 complex parts. A skilled operator might take 30 minutes to produce each part with manual machining. That's 50 hours of machining time, not counting setup and tool changes.

The same job might be completed with a CNC machine in a fraction of the time. Once the CNC program is created (which we'll discuss more later), the machine can churn out parts 24/7 with minimal human intervention. Even if each cycle takes 10 minutes, the entire batch could be completed in under 17 hours - a significant time savings.

But it's not just about raw speed. CNC machines also reduce downtime between production cycles. Tool changes, for example, can be programmed into the CNC code, allowing the machine to switch tools automatically without a human operator. This automation keeps the machine running and producing parts, further boosting efficiency.

CNC machinists may earn higher wages than manual machinists, but their productivity far outpaces their counterparts. A CNC machinist can produce more parts in less time, reducing labor costs per unit.

Consider this comparison:

In this scenario, the CNC machinist's output is four times higher than the manual machinist's, despite the higher individual wage. This productivity boost has driven the widespread adoption of CNC technology in manufacturing.

As CNC technology advances, AI-assisted CNC and CAM systems promise to further enhance productivity. AI can optimize tool paths, adapt to material variations, and predict maintenance needs, enabling machinists to operate more machines with less intervention. While the full impact of AI in CNC is still unfolding, it's an exciting development to monitor.

Transitioning to CNC doesn't eliminate the need for skilled labor. CNC machinists require a unique skill set, combining traditional machining knowledge with CNC programming and operation expertise. Investing in workforce training can help manufacturers maximize the benefits of CNC technology.

While CNC machinists may have higher individual wages, their increased productivity significantly reduces labor costs per part. As more manufacturers adopt CNC technology and explore AI, this efficiency advantage will grow, reshaping the economics of manufacturing labor.

CNC technology also enhances manufacturing efficiency by improving the quality and consistency of the parts produced. As mentioned earlier, CNC machines can execute cuts with incredible precision and repeatability. This accuracy translates into higher-quality parts with tighter tolerances.

However, CNC's impact on quality goes beyond just precision. The automated nature of CNC machining also reduces the risk of human error. With manual machining, an operator's fatigue, distraction, or miscalculation can lead to scrapped parts or rework. CNC machines don't have these human limitations – assuming all possible variables have been accounted for, they execute the programmed instructions the same way every time, resulting in consistent, high-quality parts.

This consistency is particularly important in industries with stringent quality requirements, such as food processing, aerospace, or medical device manufacturing. CNC technology allows these industries to meet exacting standards and maintain compliance with regulatory requirements.

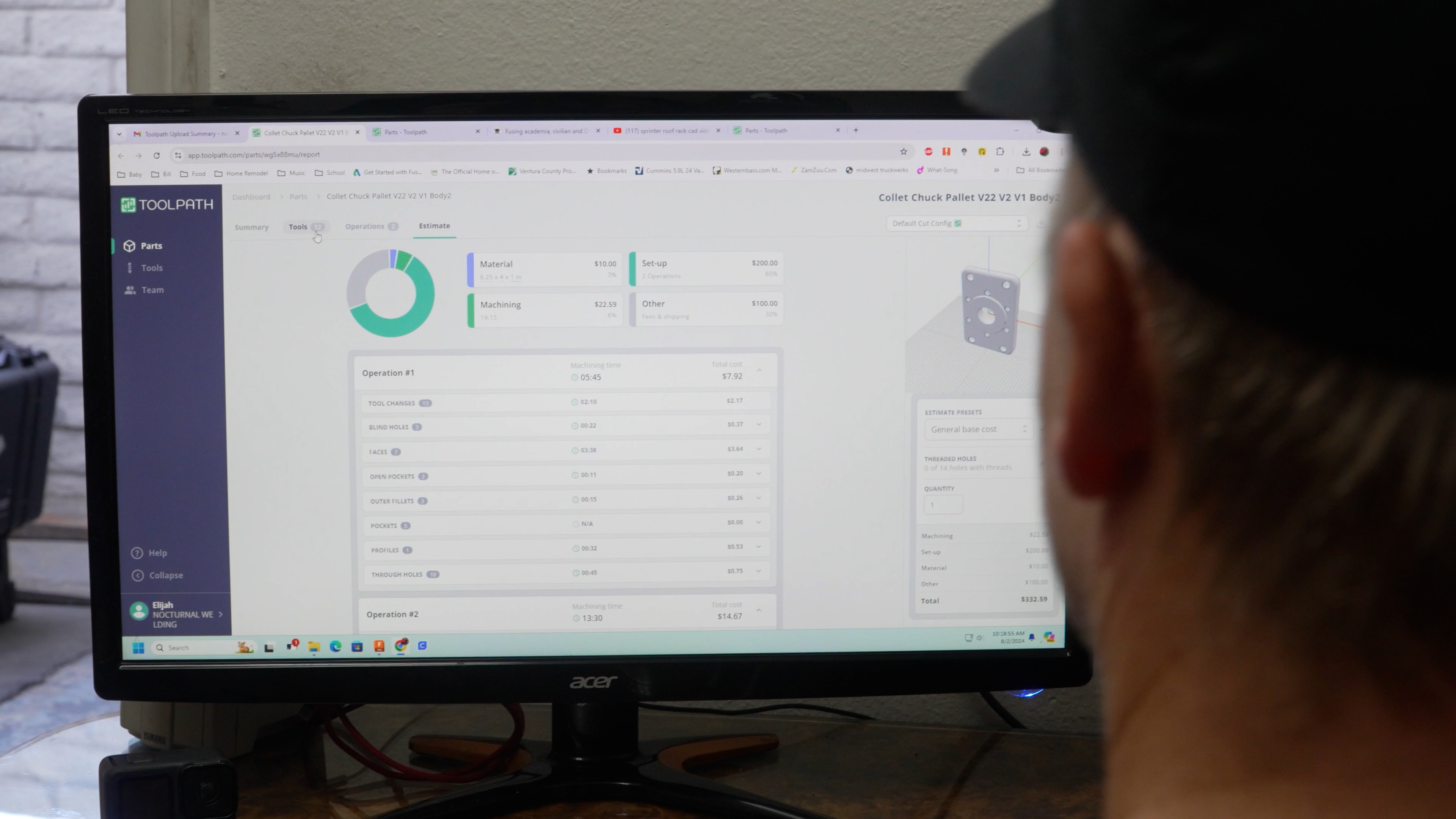

While CNC machines are incredibly efficient once they're up and running, programming remains a challenge. Creating the CNC code instructing the machine can be time-consuming, particularly for complex parts. That's where Computer-Aided Manufacturing (CAM) software comes in.

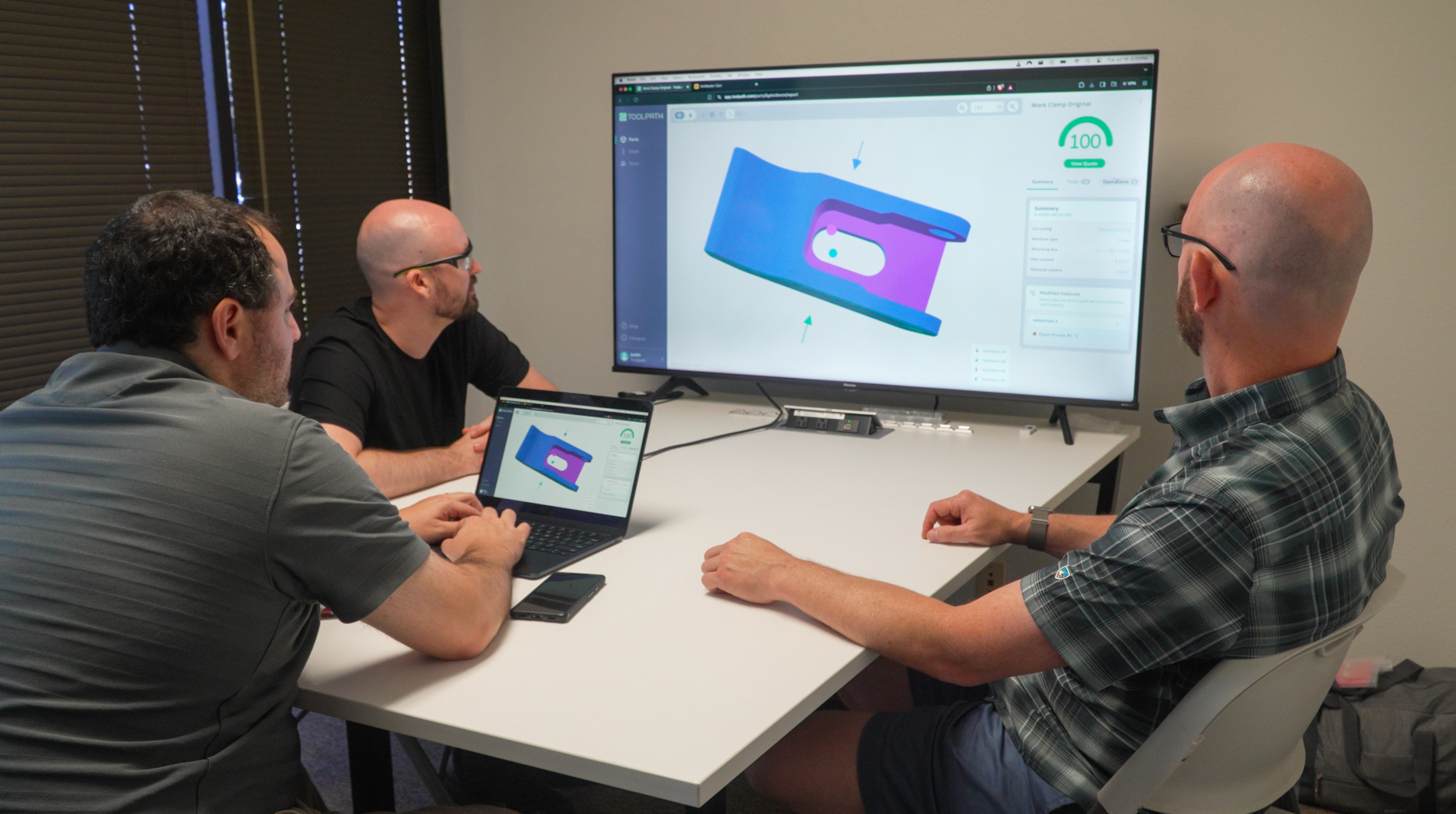

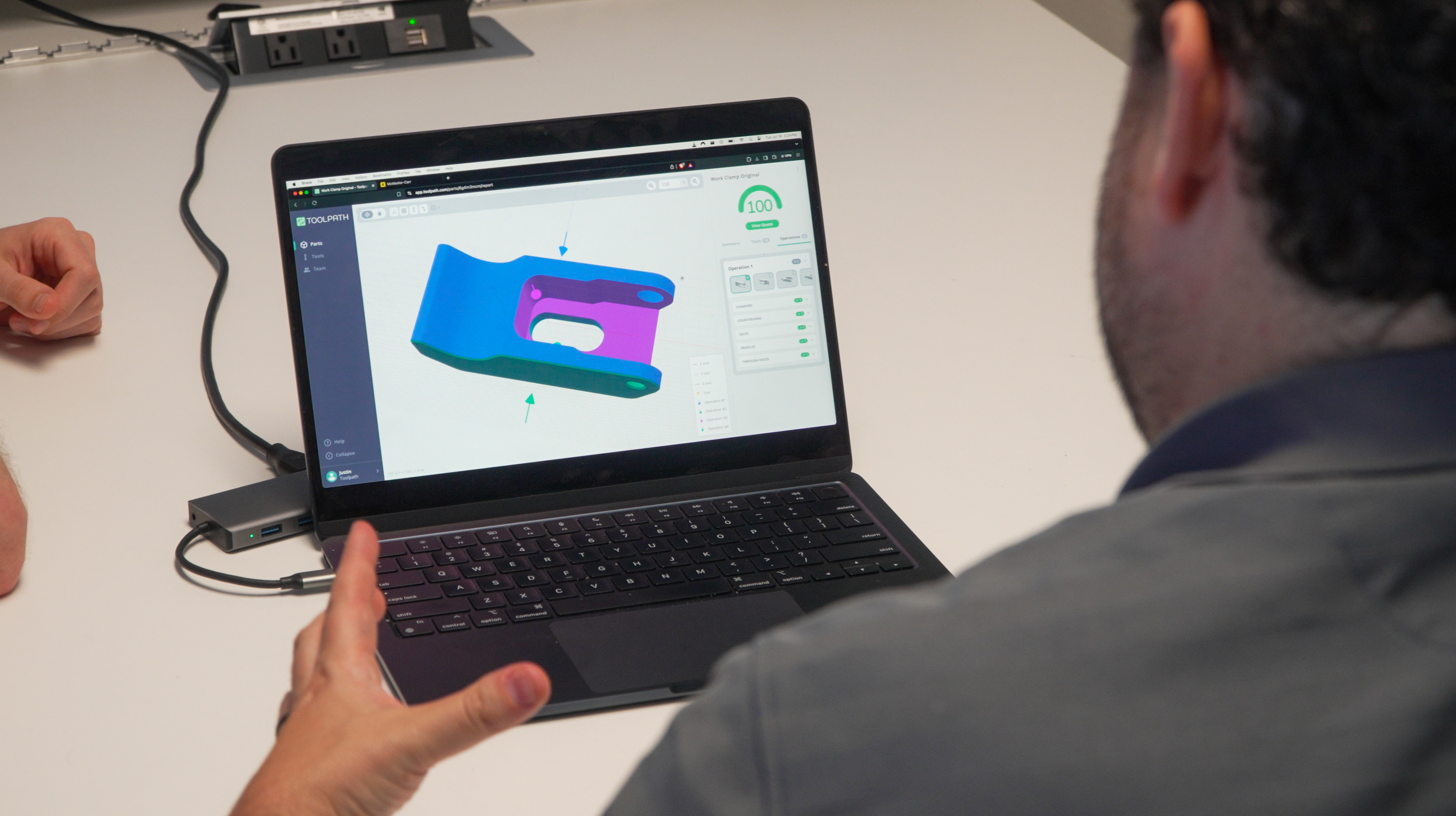

CAM software can automate much of the CNC programming process, drastically reducing the time and effort required. With CAM, designers create a 3D model of the part using Computer-Aided Design (CAD) software. The CAM software then uses this 3D model to generate the CNC code needed to produce the part.

This software streamlines the transition from design to production, reducing lead times and improving efficiency. CAM can also optimize toolpaths (the path the cutting tool follows), minimizing tool wear and maximizing machining efficiency.

For a deeper dive into the efficiency benefits of CAM software, check out Toolpath's comprehensive guide, "Mastering CAM Automation: A Guide For CNC Shops".

CNC technology has had a profound impact on manufacturing efficiency. By digitizing and automating the machining process, CNC machines enable faster production cycles, reduced labor costs, and improved part quality and consistency. CNC technology becomes an even more powerful tool for boosting manufacturing efficiency when paired with CAM software for streamlined programming.

If you're looking to take your manufacturing efficiency to the next level, Toolpath's cutting-edge CAM software is the solution. With our AI-driven automation tools and intuitive user interface, you can harness the full power of CNC technology and drive your business forward.

Ready to experience the efficiency benefits of Toolpath for yourself? Start your free trial today and see how our software can revolutionize your CNC operations.

CNC (Computer Numerical Control) technology has become the backbone of modern manufacturing automation. CNC machines have revolutionized the way...

In the competitive manufacturing world, CNC machine shops always look for ways to boost productivity and stay ahead of the game. You can...

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....