What are the advantages of CAM software?

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

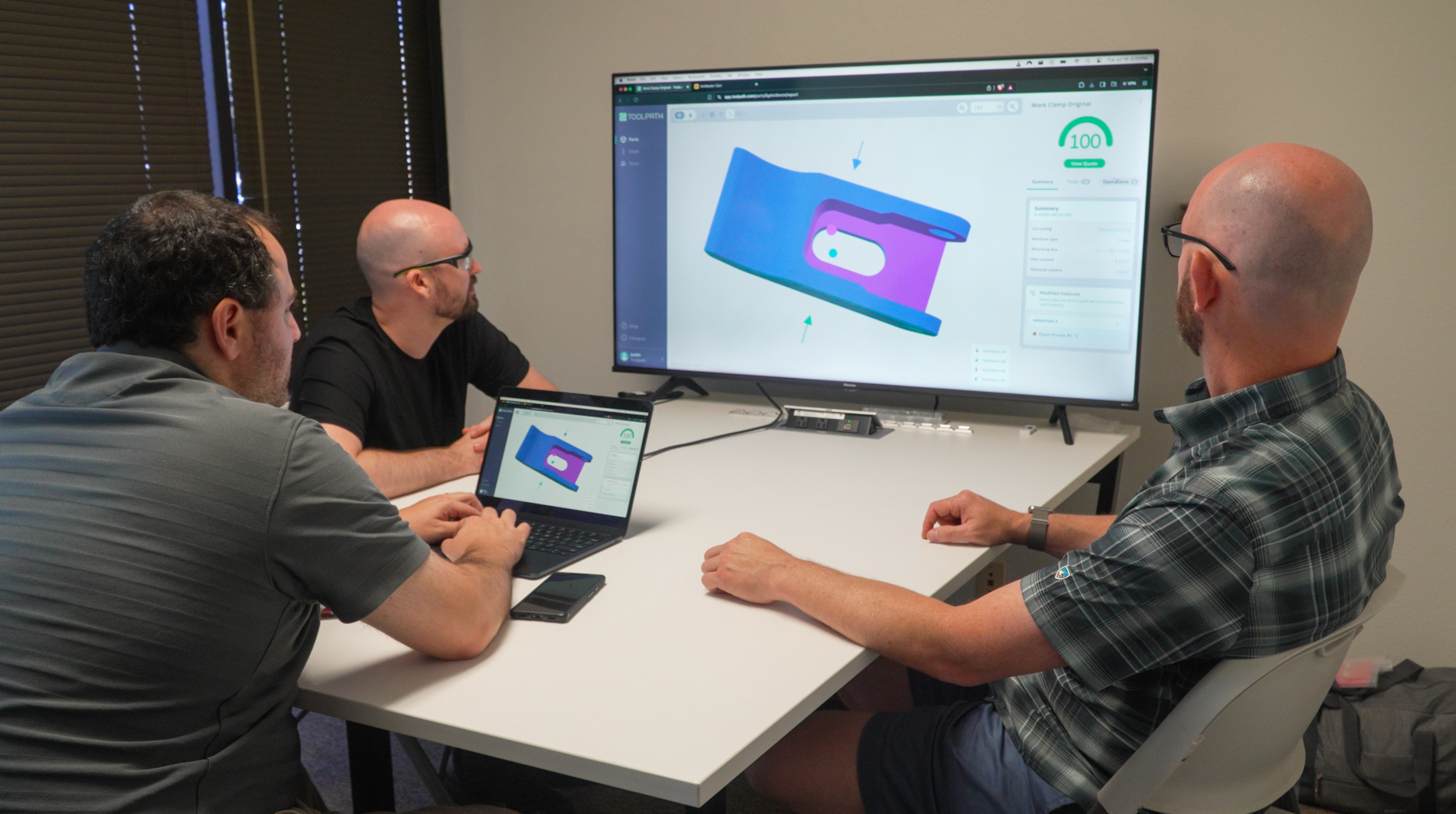

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer. From automating tedious programming tasks to optimizing toolpaths and integrating with CAD software, CAM systems bring a lot to the table. But if you had to choose just one benefit that stands out above the rest, what would it be?

To answer this question, let's explore some of the key advantages of CAM systems and weigh their impact on CNC machining operations.

One of the most apparent benefits of CAM systems is their ability to streamline and automate various aspects of the machining process. By eliminating manual programming tasks and optimizing toolpaths, CAM software can significantly reduce setup times and increase overall efficiency.

Consider a scenario where you need to produce a batch of complex parts with intricate geometries. Without a CAM system, you'd need to manually create the CNC programs, carefully considering each toolpath and potential collision. This process can be time-consuming and prone to errors, especially for less experienced machinists.

With a CAM system, however, much of this work is automated. The software can analyze the part geometry, select the appropriate tools, and generate optimized toolpaths that minimize machining time and maximize efficiency. This not only saves valuable programming time but also helps ensure that your CNC machines are running at peak performance.

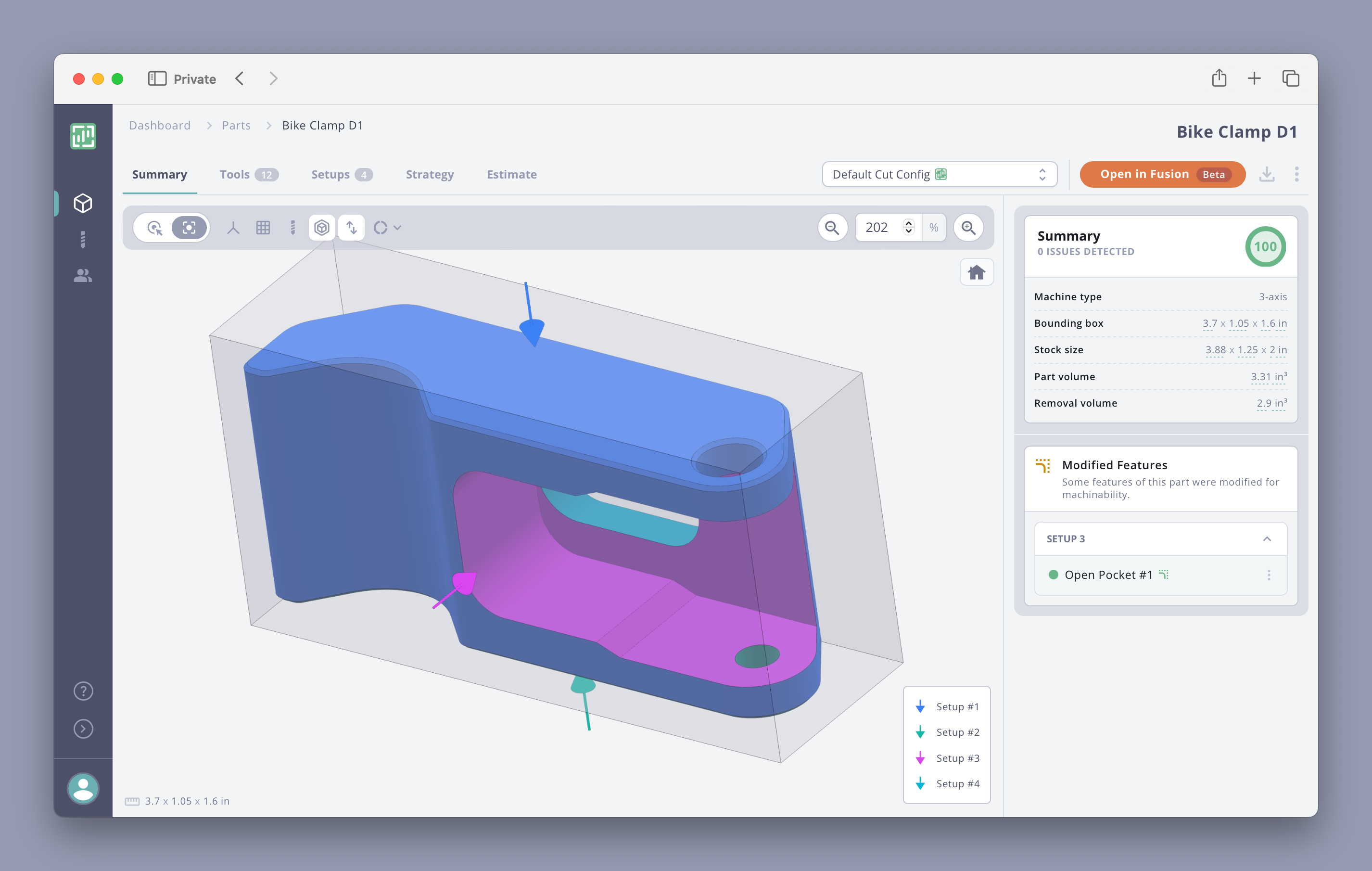

Another significant benefit of CAM systems is their ability to improve accuracy and consistency in the machining process. By relying on precise, computer-generated toolpaths and simulations, CAM software can help eliminate the human errors that can creep into manual programming.

Think about a situation where you must produce a large batch of identical parts. Even the slightest variation in the machining process can lead to inconsistencies in the final products, which can be costly in terms of scrap, rework, and customer satisfaction.

With a CAM system, you can ensure that every part is machined using the same optimized toolpaths and parameters. This consistency improves the overall quality of your output and helps reduce waste and increase profitability.

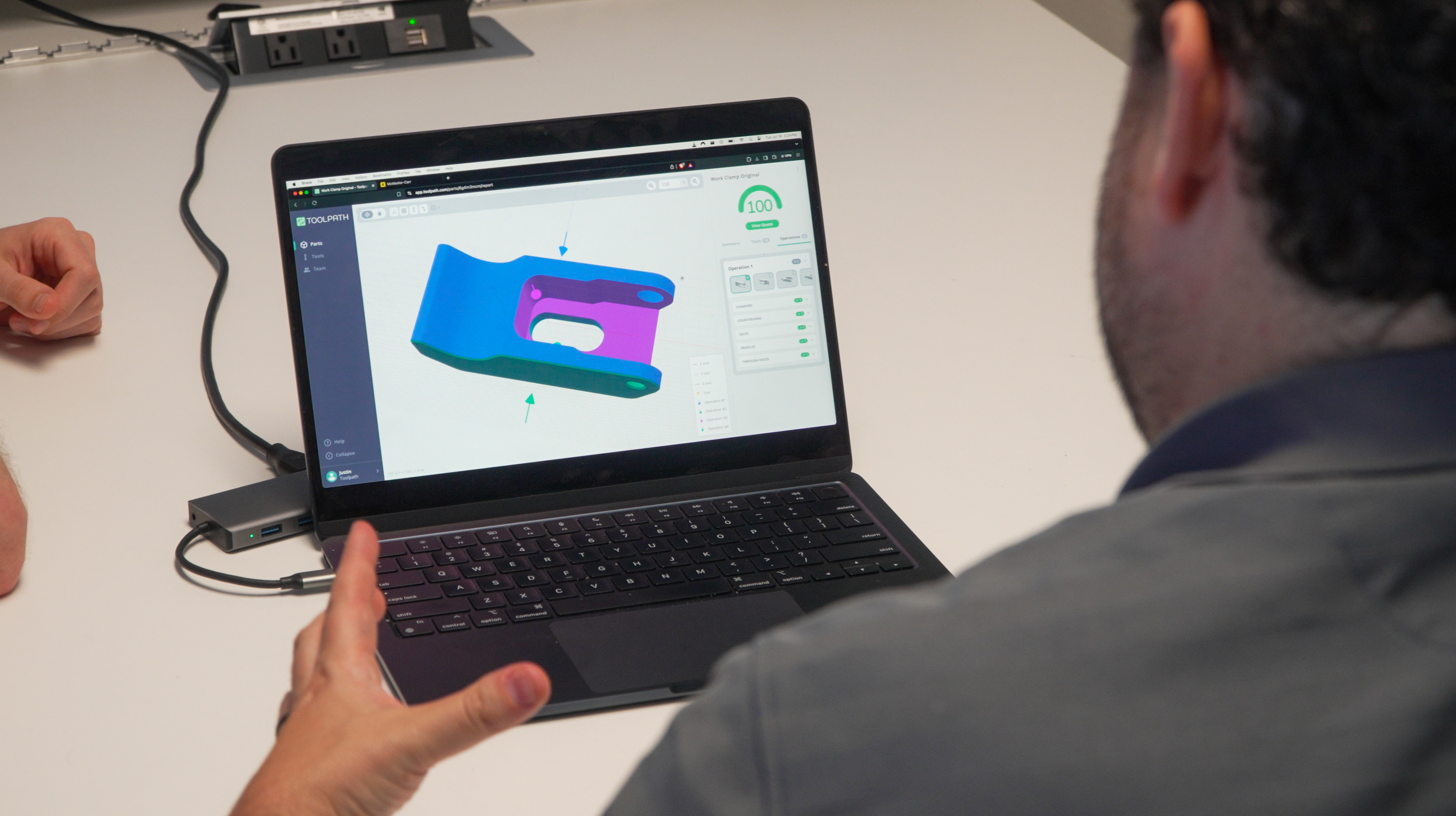

In today's fast-paced manufacturing environment, the ability to translate design intent quickly and accurately into machining instructions is crucial. This is where the seamless integration between CAD (Computer-Aided Design) and CAM systems shines.

Imagine a scenario where a design change comes in at the last minute. In a traditional setup, you'd need to manually update the CNC program to reflect the new geometry, which can be time-consuming and error-prone.

With a CAD/CAM integrated system, however, design changes can be automatically propagated to the machining instructions. This not only saves time but also reduces the risk of errors and ensures that the final product accurately reflects the designer's intent.

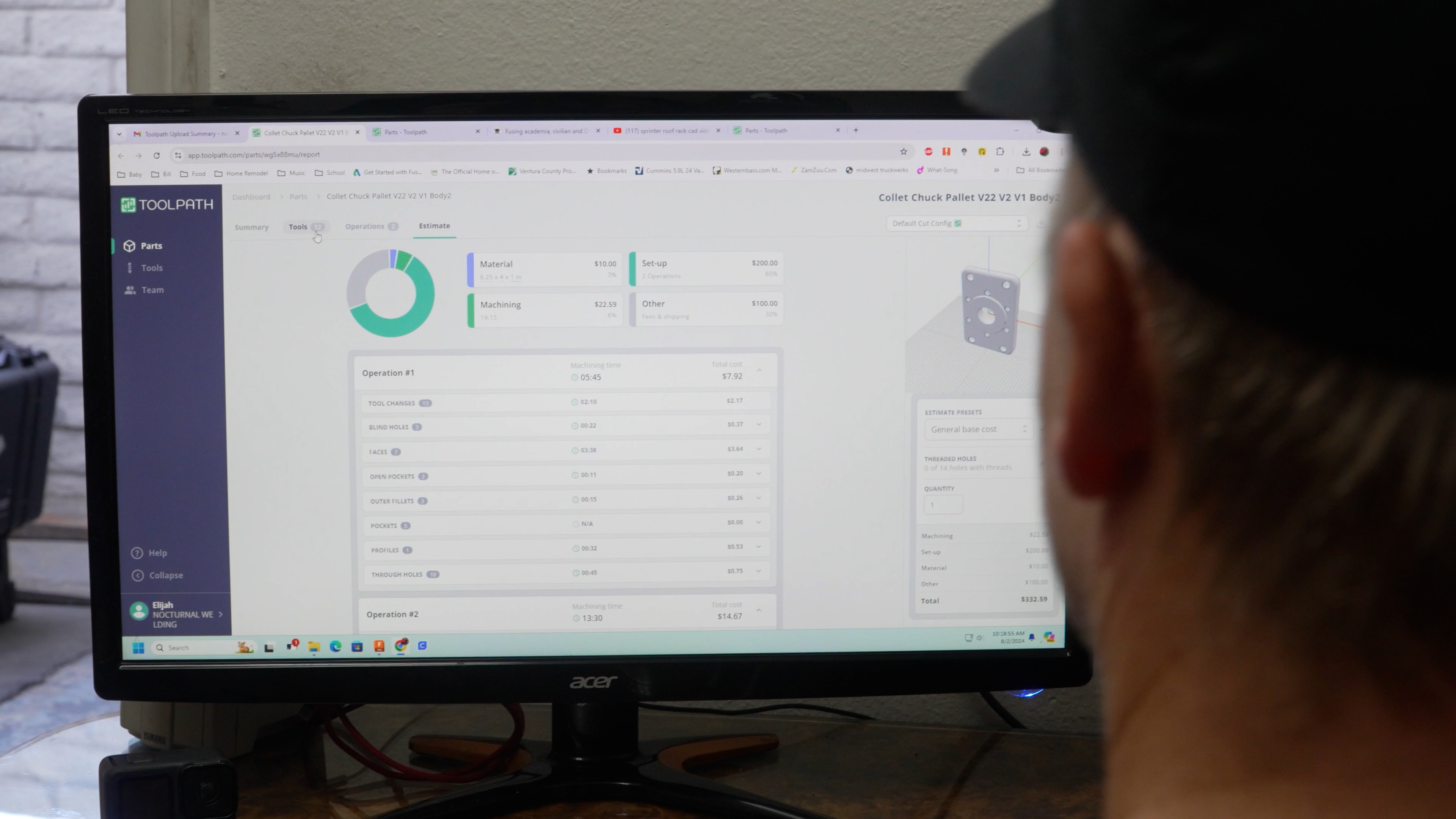

One of the most powerful features of modern CAM systems is their ability to simulate the machining process before a single chip is cut. This virtual prototyping allows machinists to identify potential issues, such as tool collisions or excessive vibrations, and make necessary adjustments before any actual machining takes place.

Consider a situation where you're working with a new material or particularly challenging part geometry. Without simulation, you'd need to rely on trial and error, which can be costly regarding time, materials, and tool wear.

With a CAM system that includes robust simulation capabilities, you can virtually test and optimize your machining strategies, ensuring that you get it right the first time. This not only saves time and money but also gives you the confidence to take on more complex and challenging projects.

While all of the benefits we've discussed are significant, one stands out as the ultimate advantage of CAM systems: precision. Whether it's through automated toolpath generation, seamless CAD/CAM integration, or virtual simulation, CAM software helps machinists achieve unparalleled levels of precision in their work.

This precision manifests itself in many ways, from the ability to hold tighter tolerances and produce more consistent parts to the reduction of scrap and rework. It's the foundation upon which all other benefits of CAM systems are built, and it's what ultimately sets them apart as game-changers for CNC machining.

So, while increased efficiency, enhanced accuracy, and seamless integration are all important, it's the precision that CAM systems enable that truly transforms the way machinists work and the quality of the parts they produce.

Now that we've explored some of the key advantages of CAM systems, it's time to turn the question back to you. What do you see as the single most significant benefit of CAM in your own machining operations?

Is it the time savings and increased efficiency that come with automation? The ability to produce more consistent and accurate parts? The seamless integration with CAD software? Or, like us, do you see precision as the ultimate game-changer?

There's no right or wrong answer, as the benefits of CAM systems can vary depending on your shop's specific needs and challenges. However, by understanding and prioritizing these advantages, you can make more informed decisions about how to leverage CAM technology to take your machining to the next level.

Interested in learning more about how CAM systems benefit your CNC machining operations? Be sure to check out our comprehensive guide, Mastering CAM Automation: A Guide For CNC Shops, and explore the advantages of cloud-based CAM solutions in our article, Benefits Of Cloud-Based CAM Solutions For Machinists.

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

In the competitive manufacturing world, CNC machine shops always look for ways to boost productivity and stay ahead of the game. You can...

If you run a CNC shop or work as a machinist, you’re likely aware of CAM (Computer-Aided Manufacturing) software. Today, more shops are exploring how...