What are the advantages of CAM software?

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

In the competitive manufacturing world, CNC machine shops always look for ways to boost productivity and stay ahead of the game. You can significantly increase your shop's efficiency and output with the right strategies and tools. In this post, we'll explore some key ways to improve productivity in your CNC machining operations.

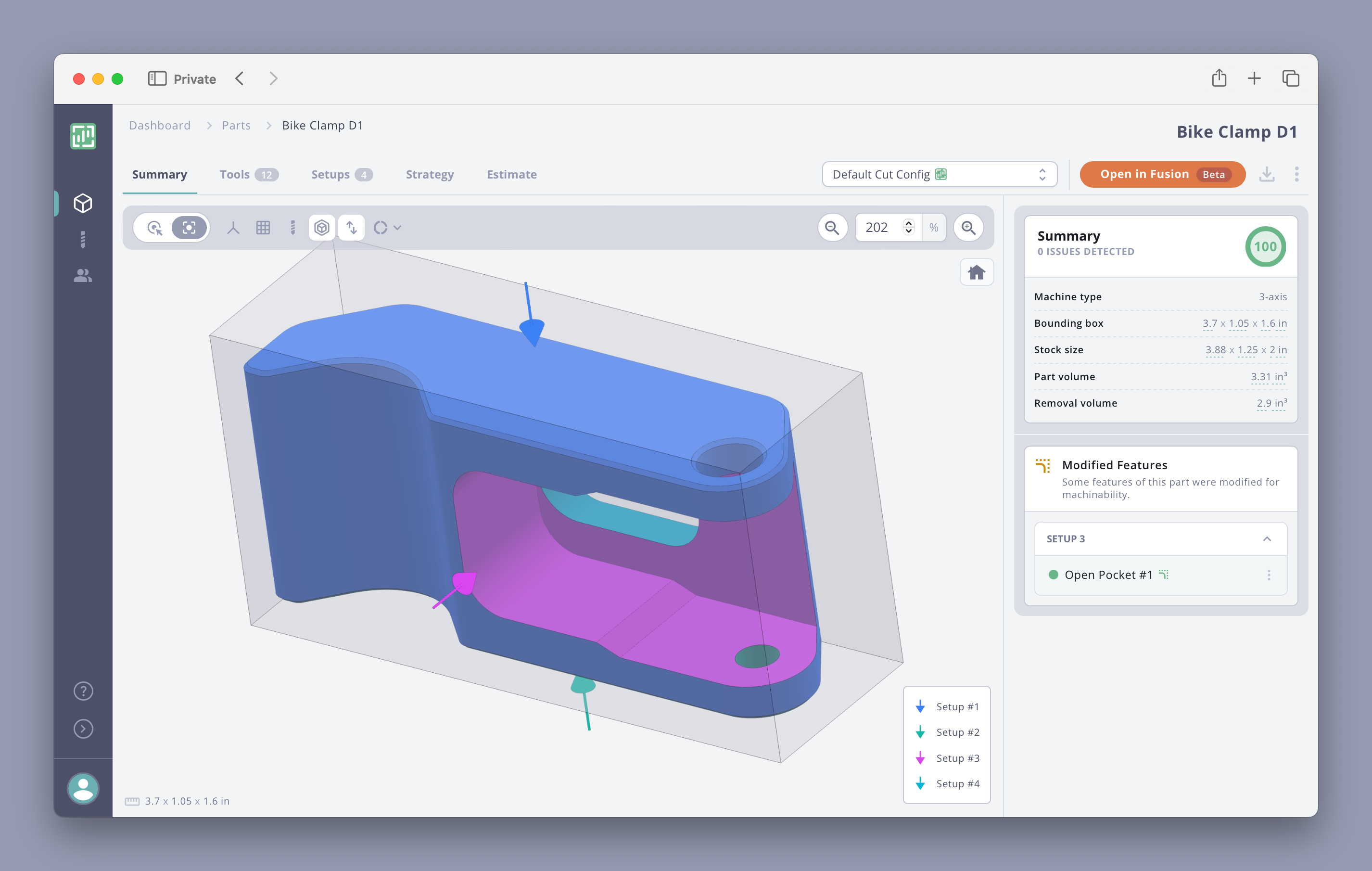

One of the most powerful tools for increasing CNC machining productivity is computer-aided manufacturing (CAM) automation. CAM software automates many of the time-consuming tasks involved in CNC programming, such as toolpath creation and optimization. Here's how CAM automation can boost your productivity:

To learn more about how CAM automation can revolutionize your shop's productivity, check out our comprehensive guide: Mastering CAM Automation: A Guide For CNC Shops.

In addition to CAM software, you can boost CNC productivity by leveraging the automation capabilities built into your CNC control. Two powerful strategies are macro programming and integration with third-party automation hardware.

Macro programming allows you to automate repetitive tasks directly on the machine. With macros, you can:

For example, suppose you have a family of parts with similar features but different dimensions. Instead of separate programs for each variation, you could create a parametric macro that adjusts based on user inputs. This would greatly reduce setup times and minimize errors.

Another productivity booster is integrating your CNC machines with third-party automation hardware like robots or conveyors. Modern CNC controllers often have built-in interfaces for this. Benefits include:

To illustrate, let's extend the previous example. If you integrated a robotic arm to load/unload the parts, you could create a macro that communicates with the robot, telling it when to load a new part and where to place the finished piece. This would enable continuous, operator-free running.

Implementing these strategies requires some upfront effort, but the benefits – reduced cycle times, increased machine utilization, and improved consistency – are substantial.

To dive deeper into the productivity benefits of programming automation, read our article: How CNC Programming Automation Boosts Productivity.

Optimizing your entire CAM workflow is important to maximize your CNC machining productivity. This means seamlessly integrating your CAD design process and your CAM programming. Here are a few tips for streamlining your workflow:

By optimizing your CAM workflow, you'll be able to move from design to production faster and more efficiently than ever before.

In addition to leveraging automation and streamlining your workflow, you can also boost productivity by adopting smart machining strategies. Here are a few to consider:

You can keep your CNC productivity at its peak by continually refining your machining strategies and leveraging the latest technologies.

Improving productivity in your CNC machine shop is all about working smarter, not just harder. Implementing CAM automation, leveraging programming automation, streamlining your workflow, and adopting smart machining strategies can dramatically increase your output and efficiency.

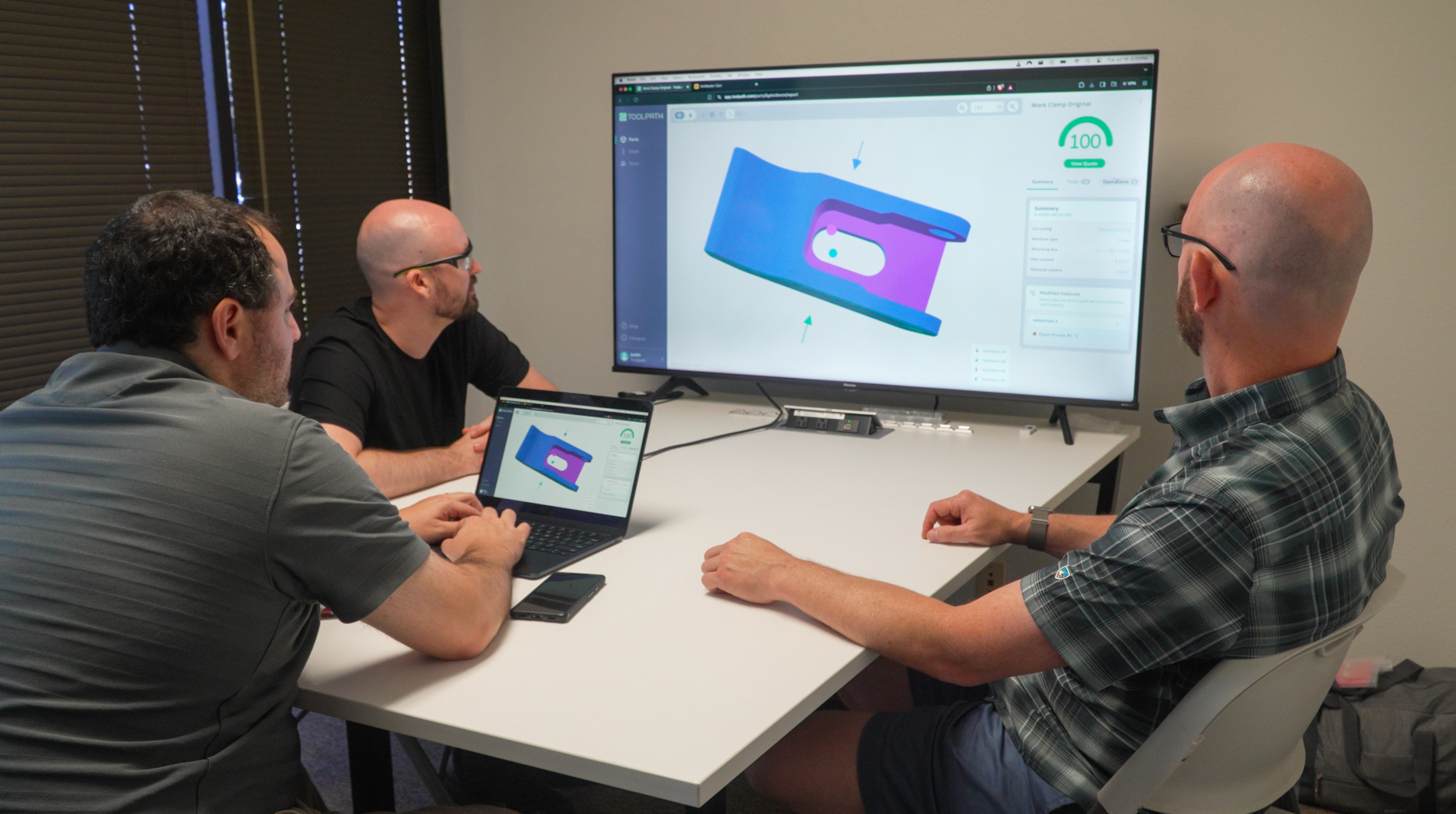

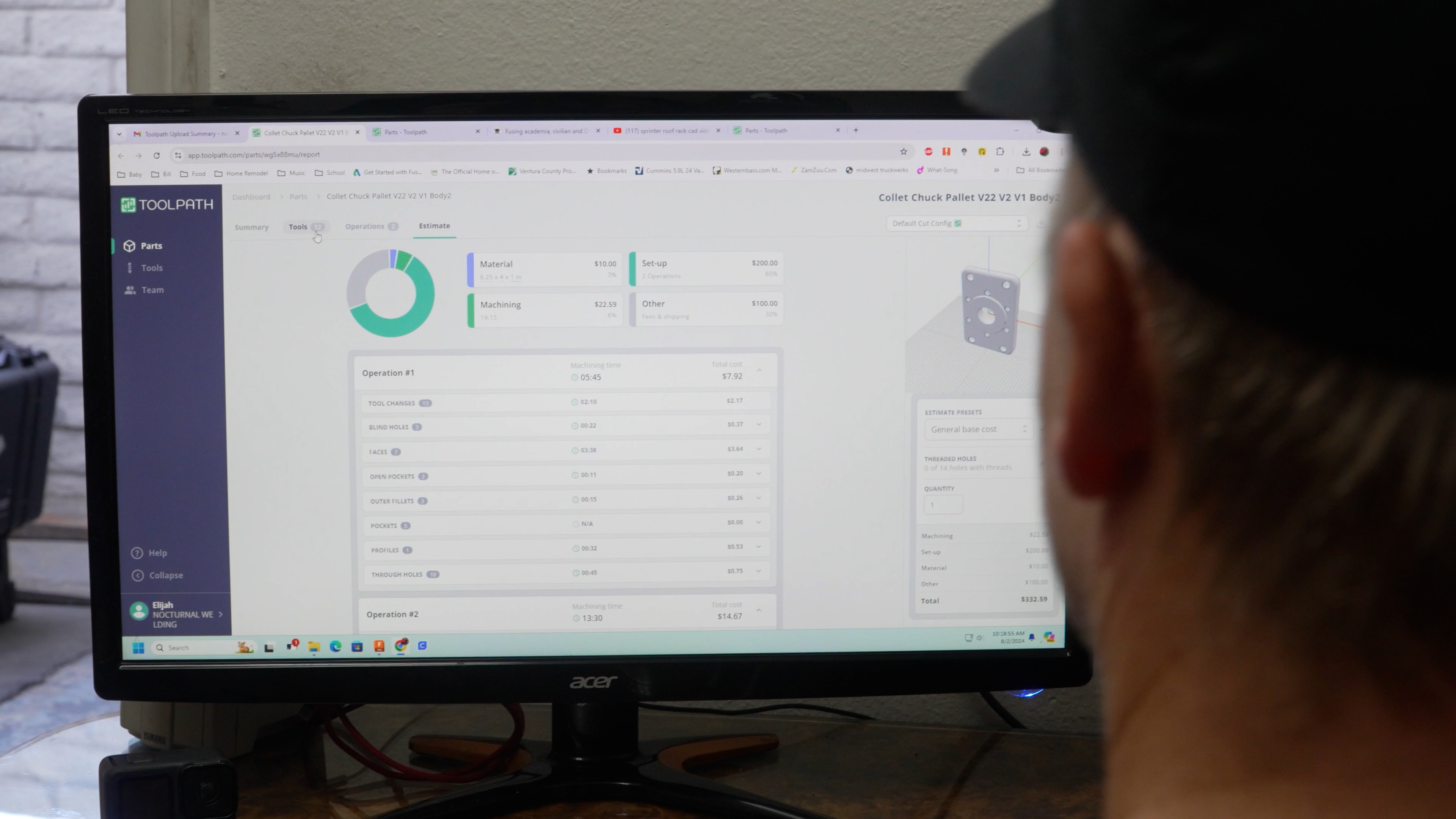

At Toolpath, we specialize in providing powerful, user-friendly CAM solutions that help CNC shops of all sizes maximize their productivity. With our AI-powered automation tools, cloud-based collaboration platform, and expert support, we can help you take your machining productivity to the next level.

To experience the productivity benefits of Toolpath for yourself, Start a Free Trial Today. Let us show you how our cutting-edge CAM software can transform your CNC machining operations!

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

In the world of manufacturing, efficiency is the name of the game. The more efficiently you can produce high-quality parts, the more competitive your...

CNC (Computer Numerical Control) technology has become the backbone of modern manufacturing automation. CNC machines have revolutionized the way...

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...