What is the most widely used CAM software?

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software streamlines your processes, reduces errors, and helps you get the most out of your machines. But with so many options available, how do you choose the one that works best for your shop? In this post, we'll explore the key features to look for and how they can transform your CNC operations.

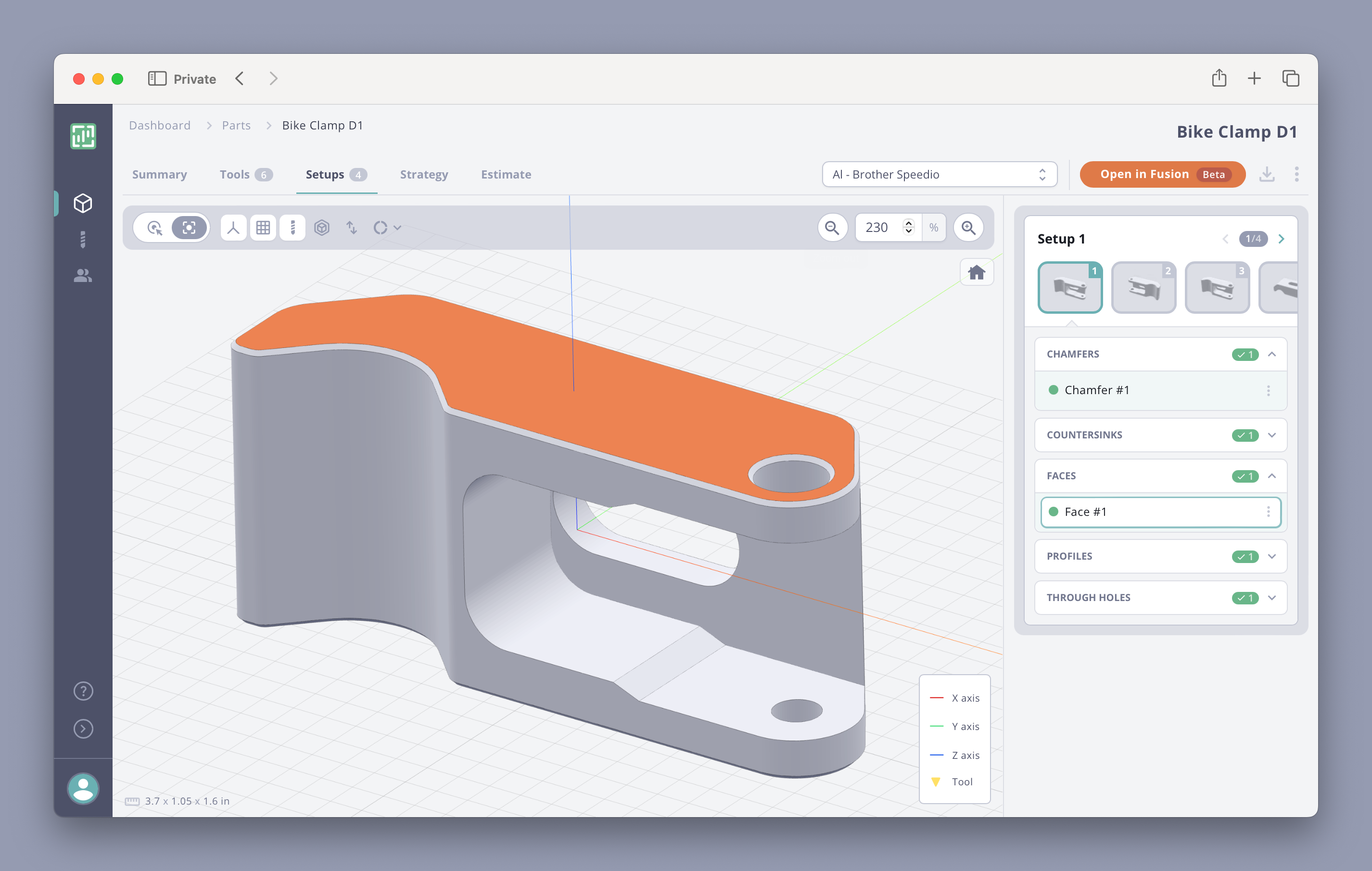

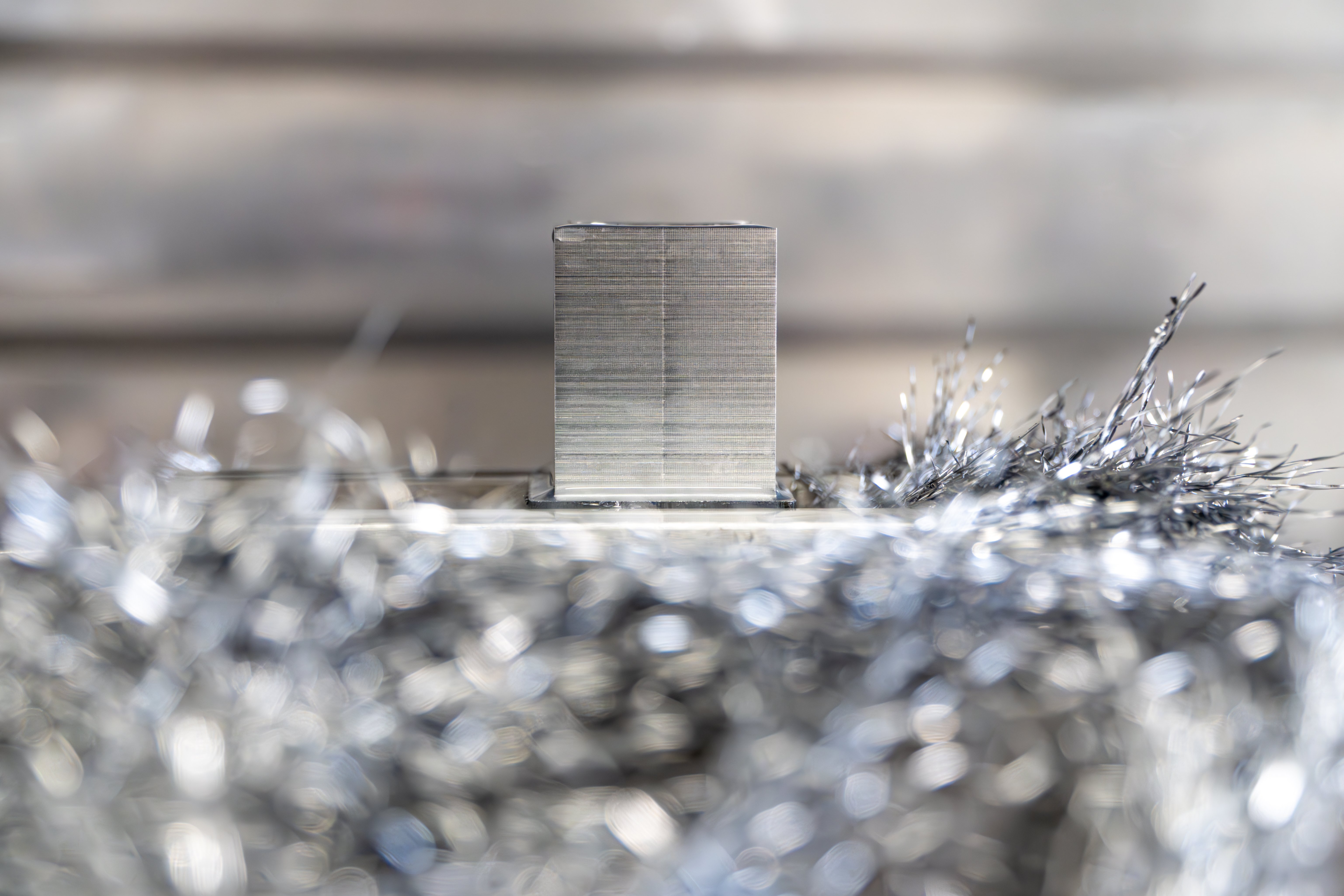

The importance of CAM software in CNC machiningAt the heart of any successful CNC operation is powerful Computer-Aided Manufacturing (CAM) software. CAM software is responsible for translating your designs into machine-readable instructions, optimizing toolpaths, and ensuring that your CNC machines produce parts accurately and efficiently. Some of the critical capabilities of CAM software include:

To learn more about how CAM automation is revolutionizing the industry, check out our comprehensive guide, Mastering CAM Automation: A Guide For CNC Shops.

When evaluating CNC software options, there are several key features to consider:

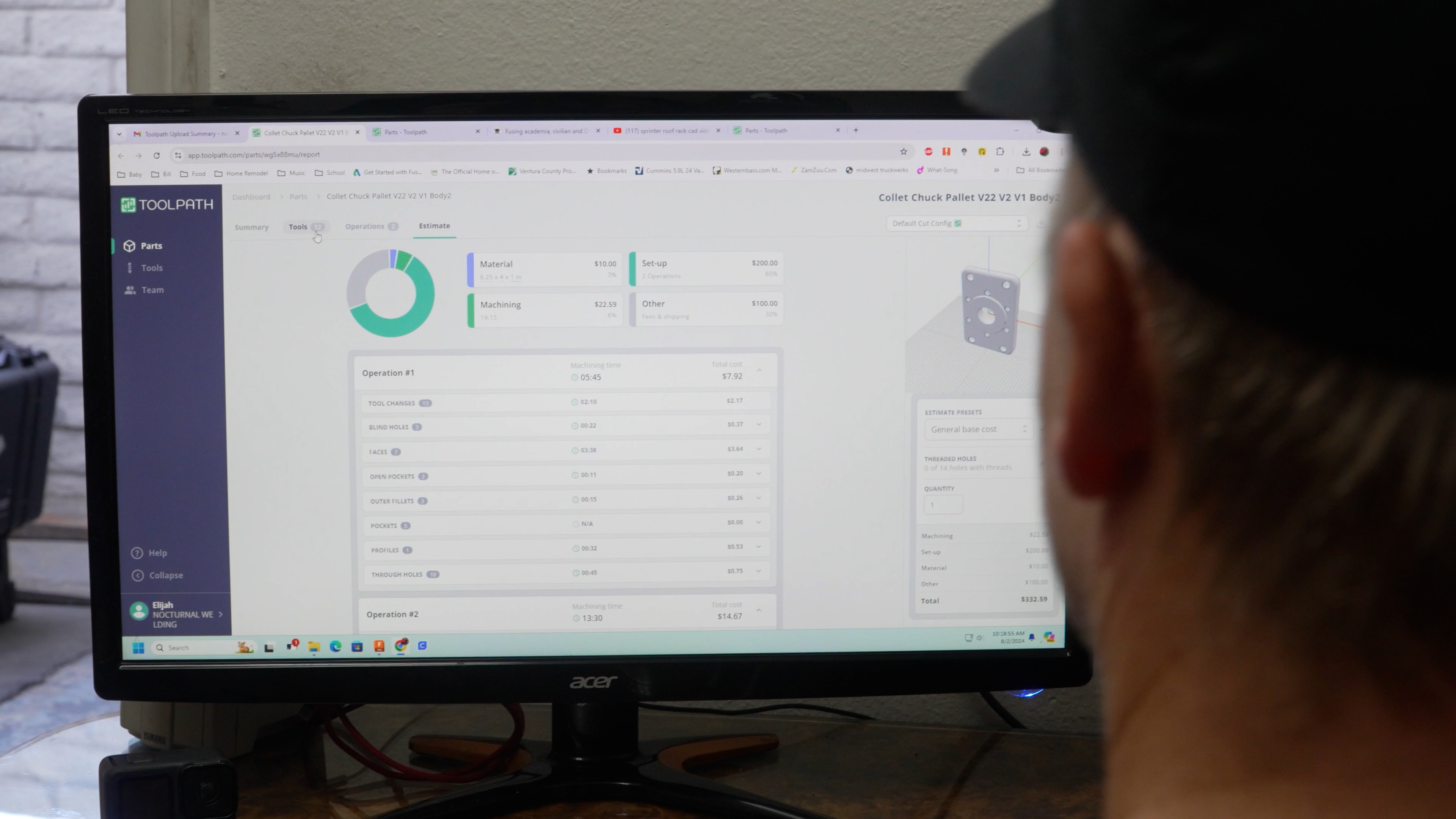

As mentioned earlier, post-processing is a critical component of any CAM software. The post-processor is responsible for converting the generic toolpaths generated by your CAM software into machine-specific G-code that takes into account your CNC machine's unique capabilities and limitations.

When evaluating CNC software, it's essential to consider the breadth and quality of the post-processors included. Some software providers offer a wide range of post-processors for different machine types and controllers, while others may have a more limited selection. Sometimes, you may need to purchase additional post-processors or have custom post-processors developed for your specific needs.

The cost of post-processors can vary significantly depending on the software provider and the complexity of your requirements. Some CAM software includes a basic set of post-processors in the base price, while others charge extra for each additional post-processor. Autodesk stirred up the industry, by providing hundreds of ‘open source’ post-processors for free with their Fusion CAM product. Invariably, each CNC machine is unique in some way, so custom post-processor development is inevitable and can, at times, be expensive, with prices ranging from a few hundred to several thousand dollars.

When budgeting for CNC software, it's important to factor in the cost of post-processors and to carefully evaluate your needs. While choosing a cheaper option with a limited post-processor library may be tempting, this can lead to inefficiencies and compatibility issues down the line. Investing in a comprehensive, high-quality post-processing system can pay off in the long run by ensuring that your CNC machines run at their full potential.

In addition to choosing the right CNC software, implementing smart CAM strategies can help you get the most out of your machines and streamline your operations. Here are a few strategies to consider:

To dive deeper into these and other smart CAM strategies, be sure to read our article, Top Smart CAM Strategies For Small CNC Shops.

Choosing the best CNC software for your shop is a critical decision that can significantly impact your productivity, quality, and profitability. By prioritizing features like ease of use, robust post-processing capabilities, scalability, simulation tools, and AI-driven optimization, you can ensure that your CNC machines are running at their full potential.

When evaluating your options, be sure to consider the breadth and quality of the post-processors included, as well as the associated costs. While investing in a comprehensive post-processing system may require a higher upfront investment, it can pay off in the long run by ensuring that your machines are compatible with your software, running efficiently, and potentially even improving integration with other business systems.

Finally, don't forget to implement smart CAM strategies like standardizing your tooling, optimizing your workholding, and automating material handling. By taking a holistic approach to your CNC operations, you can unlock new productivity levels and stay ahead of the competition.

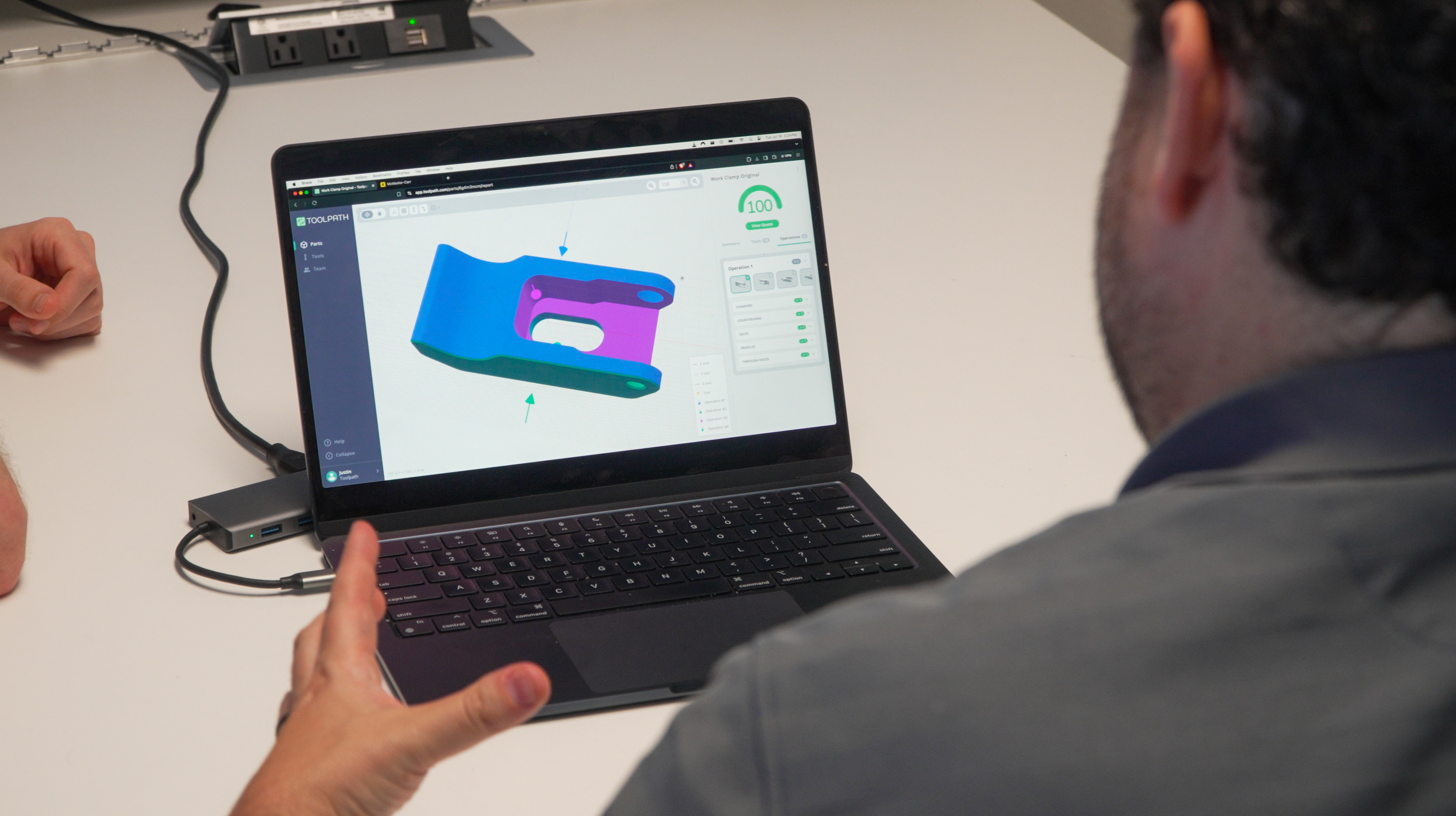

Ready to experience the benefits of advanced CNC software for yourself? Start your free trial of Toolpath today and discover how our AI-powered optimization tools, intuitive interface, and extensive post-processor library can revolutionize your CNC operations.

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

In today's rapidly evolving manufacturing landscape, choosing the right Computer-Aided Manufacturing (CAM) software can make or break your CNC shop's...

If you’re working adjacent to CNC machining, you’ve probably heard the terms CAD, CAM, and automation tossed around. While these tools are often...

If you run a CNC shop or work as a machinist, you’re likely aware of CAM (Computer-Aided Manufacturing) software. Today, more shops are exploring how...

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....