What software works best when operating a CNC?

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

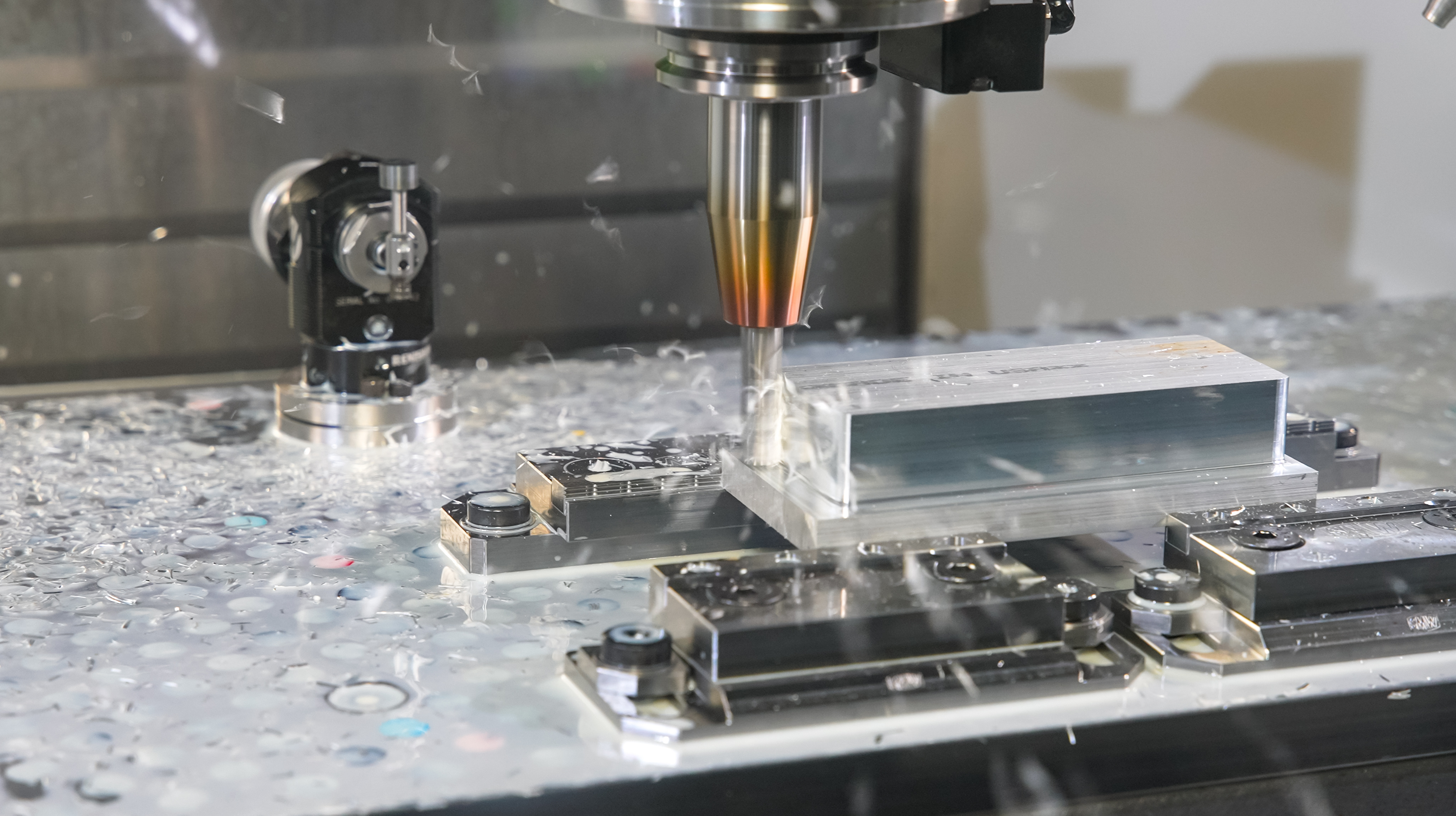

In today's rapidly evolving manufacturing landscape, choosing the right Computer-Aided Manufacturing (CAM) software can make or break your CNC shop's efficiency and competitive edge. Whether you're a small job shop looking to scale up or a large operation aiming to optimize complex workflows, your choice of CAM software will significantly impact your productivity, quality, and bottom line.

Based on the latest market analysis and user adoption rates, we've compiled a comprehensive overview of the top 10 CAM software solutions that are shaping the industry in 2024. We'll explore what makes each option unique and help you understand which might be the best fit for your specific needs.

Before diving into the rankings, it's important to understand why this decision is so crucial. Modern manufacturing faces unprecedented challenges and opportunities:

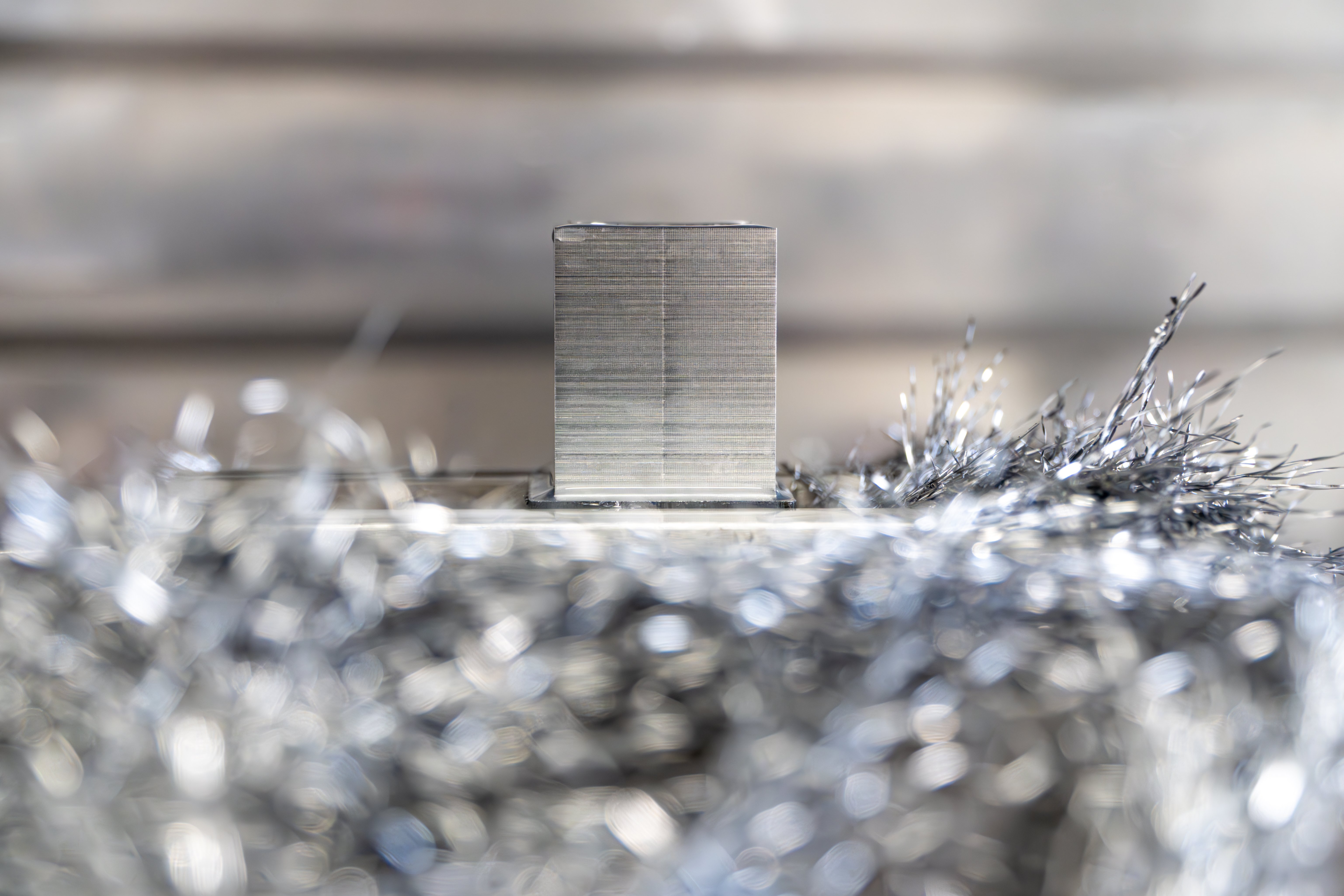

Manufacturing operations are becoming increasingly complex, with demands for faster turnaround times and higher precision than ever before. In addition, the manufacturing workforce is changing, with large numbers of experienced machinists retiring and a smaller number of young, eager, and tech-savvy professionals entering the job market. The right CAM software doesn't just help you meet these challenges; it transforms them into competitive advantages. To learn more about maximizing your CAM software's potential, check out our comprehensive guide on Mastering CAM Automation: A Guide For CNC Shops.

Market share: 14.5% (Particularly strong in North America)

Growth rate: 4.6% year-over-year

Best for: General CNC machining, job shops, and educational institutions

Having been a player in the CAM market for several decades, Mastercam leads the pack with its combination of user-friendly interface and powerful capabilities. Its extensive toolpath options and strong educational presence have helped maintain its position as North America's most widely adopted CAM solution. The software excels in providing accessible yet powerful tools for both newcomers and experienced machinists. Its fundamentally offline and standalone nature is attractive to many job shops manufacturing sensitive parts.

Market share: 13.8%

Growth rate: 15% year-over-year

Best for: Modern, digital manufacturing environments

A relatively young upstart in this industry, Autodesk Fusion's cloud-based, fully integrated CAD/CAM/PLM platform is revolutionizing how teams collaborate on manufacturing projects. Its automated CNC programming capabilities and seamless integration with Autodesk's ecosystem make it particularly attractive for shops embracing digital transformation. Fusion has leaped ahead with significant 5-axis capabilities in recent years, and its fresh and innovative approach means it’s favored amongst the next-generation workforce. The software's rapid adoption rate reflects its success in meeting the evolving needs of modern manufacturing.

Market share: 8.1%

Growth rate: 4.6% year-over-year

Best for: Aerospace, automotive, and medical device manufacturers

Siemens NX CAM's advanced multi-axis machining capabilities and robust robotic programming features stand out. Its strong presence in European high-precision manufacturing sectors testifies to its capabilities in handling complex machining operations. NX is the most complete integrated CAD/CAM product in this cohort.

Market share: 4.9%

Growth rate: 4.1% year-over-year

Best for: Complex toolpaths and advanced surface finishing

Misc: Used by over 50% of major mold manufacturers worldwide

PowerMILL's specialized focus on high-speed machining and the mold and die industry has earned it a dedicated following. Its advanced surface finishing capabilities make it particularly valuable for shops focusing on high-end mold production.

Market share: 4.1%

Growth rate: 3.9% year-over-year

Best for: Versatile machining operations

Misc: Used by over 10% of the precision machining market

ESPRIT's comprehensive coverage of various machining processes – from milling and turning to wire EDM – makes it a versatile choice for shops handling diverse projects. Its strong presence in Europe and Asia reflects its capability to meet international manufacturing standards.

Market share: 3.8%

Growth rate: 10.5% year-over-year

Best for: High-precision parts requiring sophisticated 5-axis machining

Strength: Multi-axis efficiency & automation

hyperMILL's exceptional 5-axis machining solutions and extensive automation features have made it a favorite in the aerospace, automotive, and medical sectors. Its advanced capabilities can be game-changing for shops specializing in complex, high-precision parts.

Market share: 3.5%

Growth rate: 19.4% year-over-year

Best for: SOLIDWORKS users seeking integrated CAD/CAM

SolidCAM's tight integration with SOLIDWORKS and innovative iMachining technology offers significant advantages for shops already invested in the SOLIDWORKS ecosystem. Its ability to reduce cycle times while maintaining tool life makes it particularly attractive for high-volume operations. SolidCAM also offers integration for Autodesk’s Inventor CAD product, providing a very capable offline integrated CAM product for those who can’t work with their data on public cloud infrastructure.

Market share: 2.6%

Growth rate: 3.5% year-over-year

Best for: Complex mold and die operations

Misc: 6% share in European tooling industry

Tebis shines in automated CAD/CAM workflows and advanced simulation capabilities. Its strong presence in the European tooling industry speaks to its effectiveness in handling complex mold and die operations.

Market share: 2.1%

Growth rate: 8% year-over-year

Best for: Complex part machining requiring integrated workflows

Misc: Popular in French and German markets

TopSolid'Cam's fully integrated CAD/CAM approach and intelligent tool management make it particularly effective for shops requiring a seamless design-to-manufacturing process. Its closed-loop workflow helps maintain consistency and quality throughout the manufacturing process. Topsolid’s software portfolio is extremely broad, making this a very attractive option for businesses chasing a high level of native integration across various business systems.

Market share: 1.9%

Growth rate: 7.2% year-over-year

Best for: Multi-axis machining and turn-mill

GibbsCAM is widely recognized for its robust multi-axis machining capabilities and powerful toolpath control, though it has a steeper learning curve compared to some competitors. Its flexibility in programming complex CNC machines makes it a strong solution for industries requiring high precision, such as aerospace and medical device manufacturing. Its ability to handle both simple and complex machining tasks efficiently has contributed to its steady adoption growth.

Regardless of which solution you choose, success lies in how effectively you implement and utilize your CAM software. Small and medium-sized shops, in particular, can benefit from smart implementation strategies. Check out our guide on Top Smart CAM Strategies For Small CNC Shops for practical insights on maximizing your CAM software's potential.

The CAM software landscape is evolving rapidly, with artificial intelligence and cloud computing reshaping what's possible in manufacturing. Modern solutions are increasingly incorporating AI-driven optimizations, cloud collaboration features, and advanced automation capabilities. These developments are making sophisticated manufacturing processes more accessible to shops of all sizes.

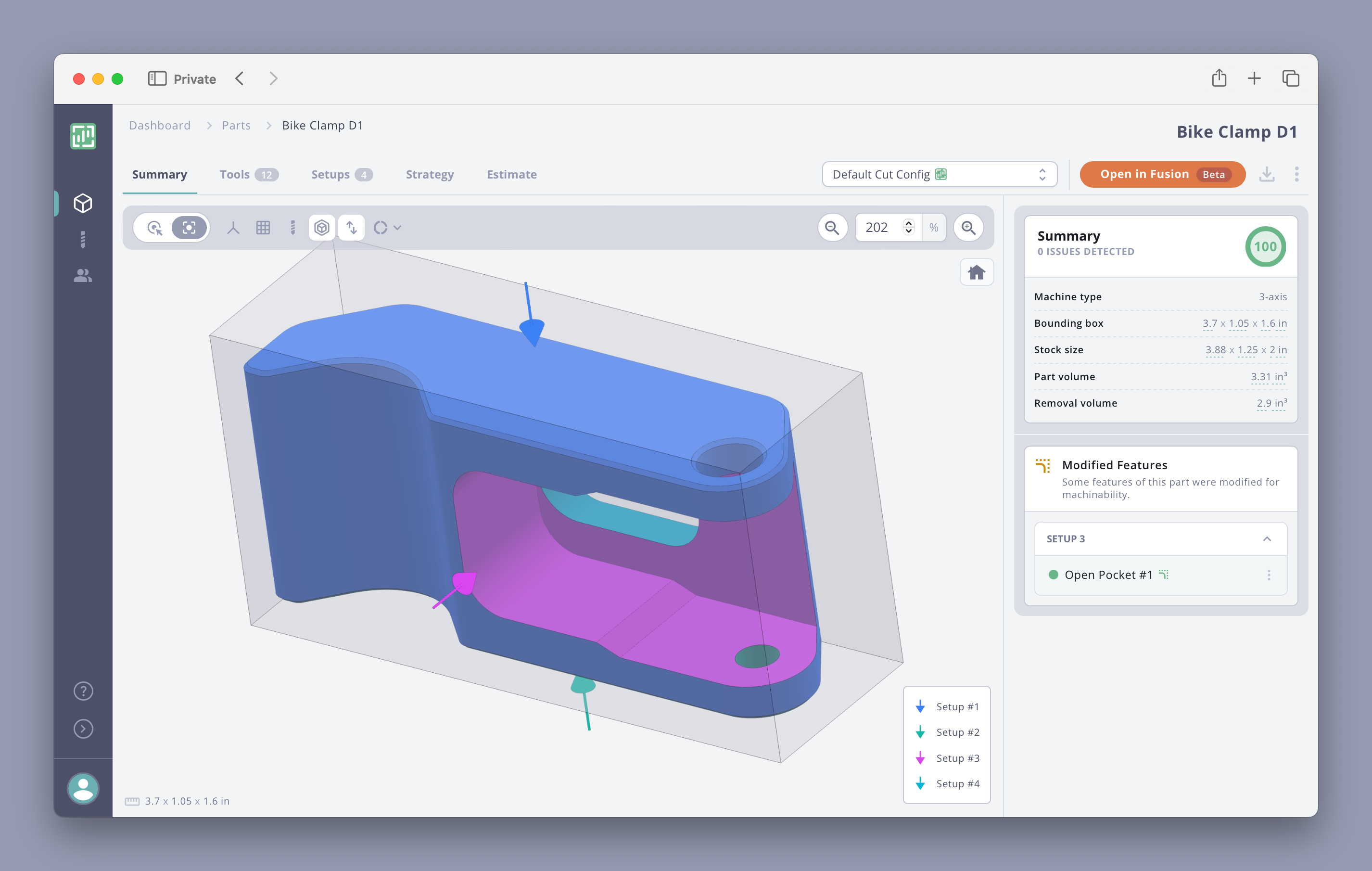

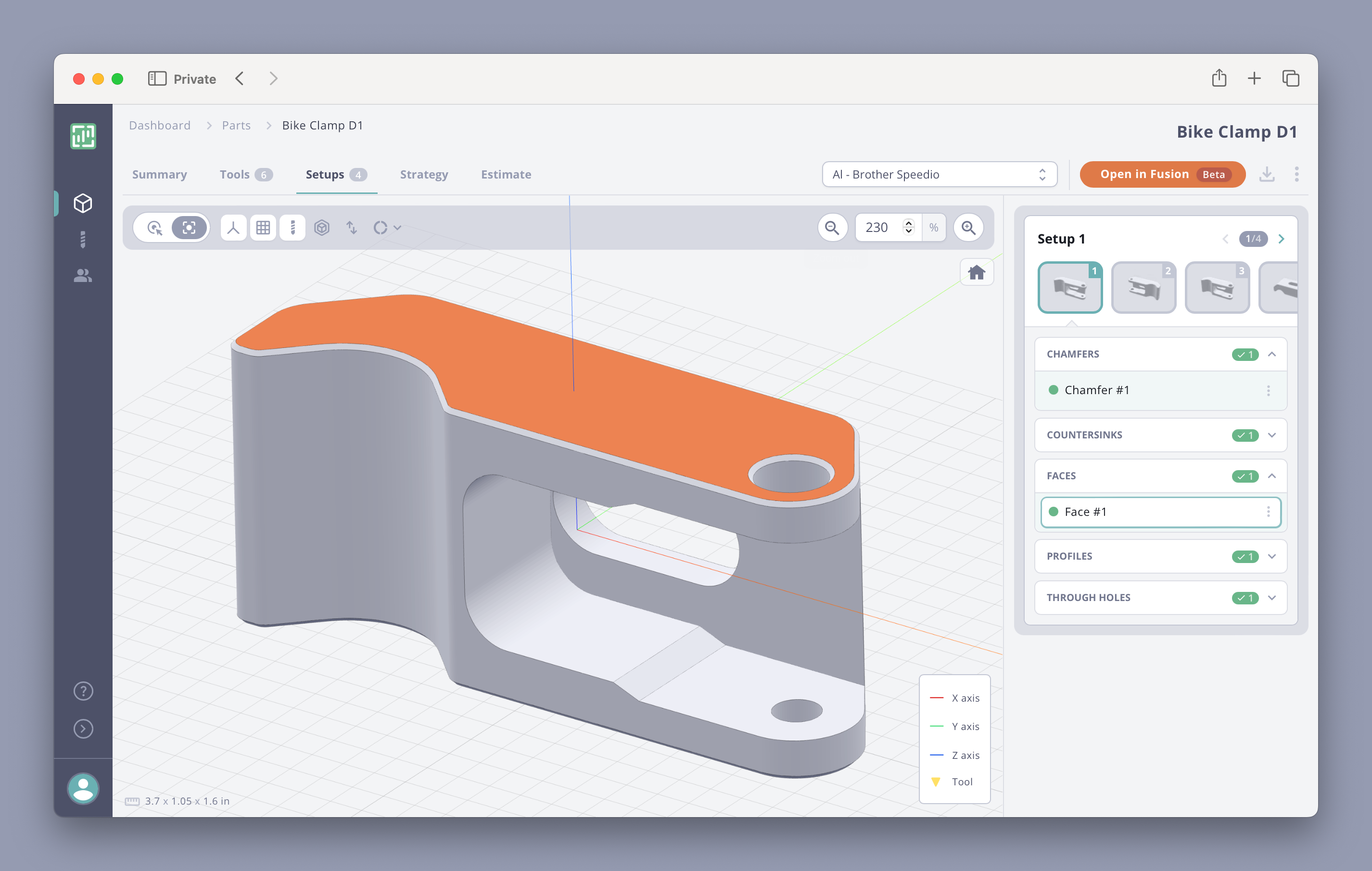

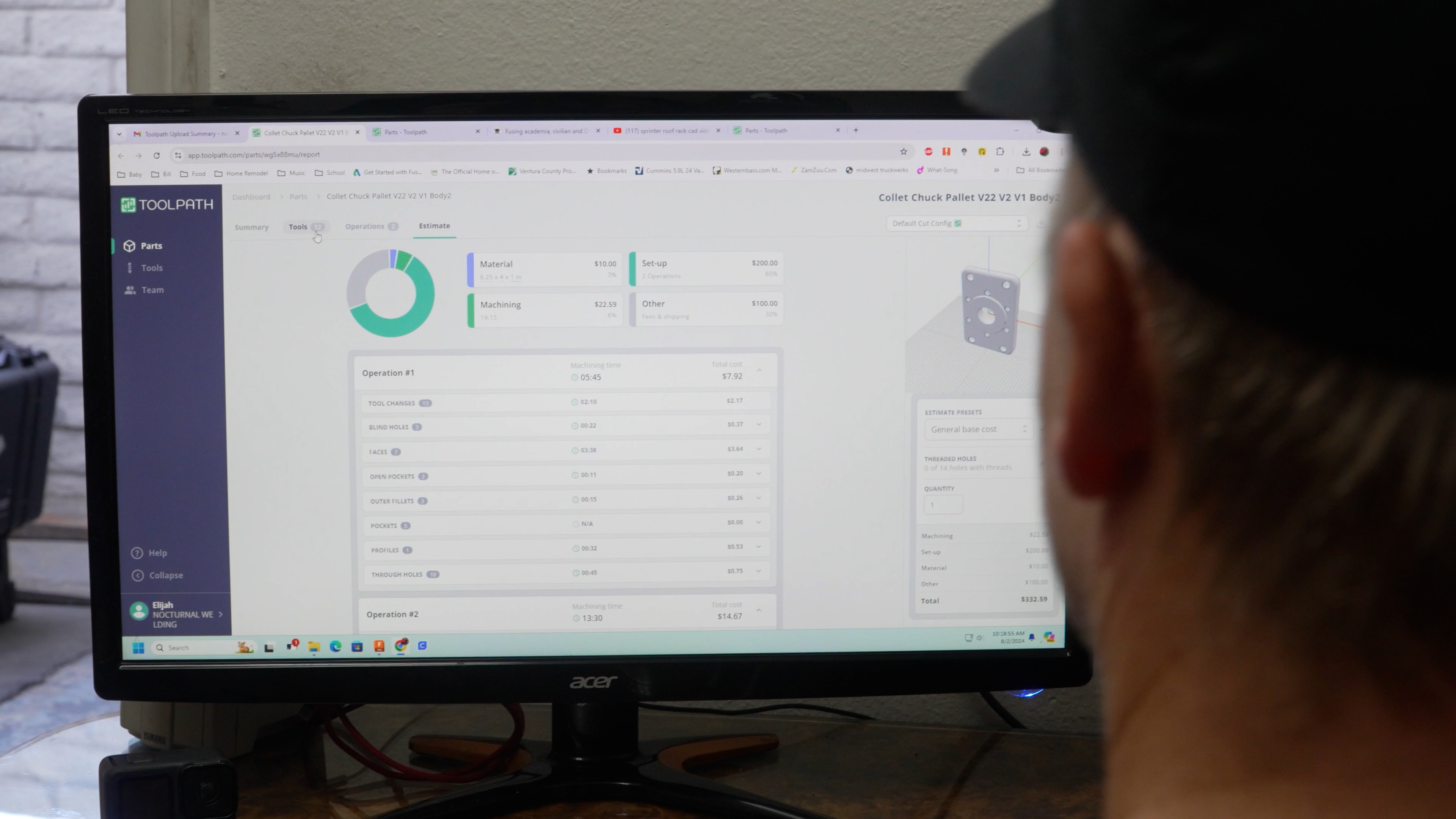

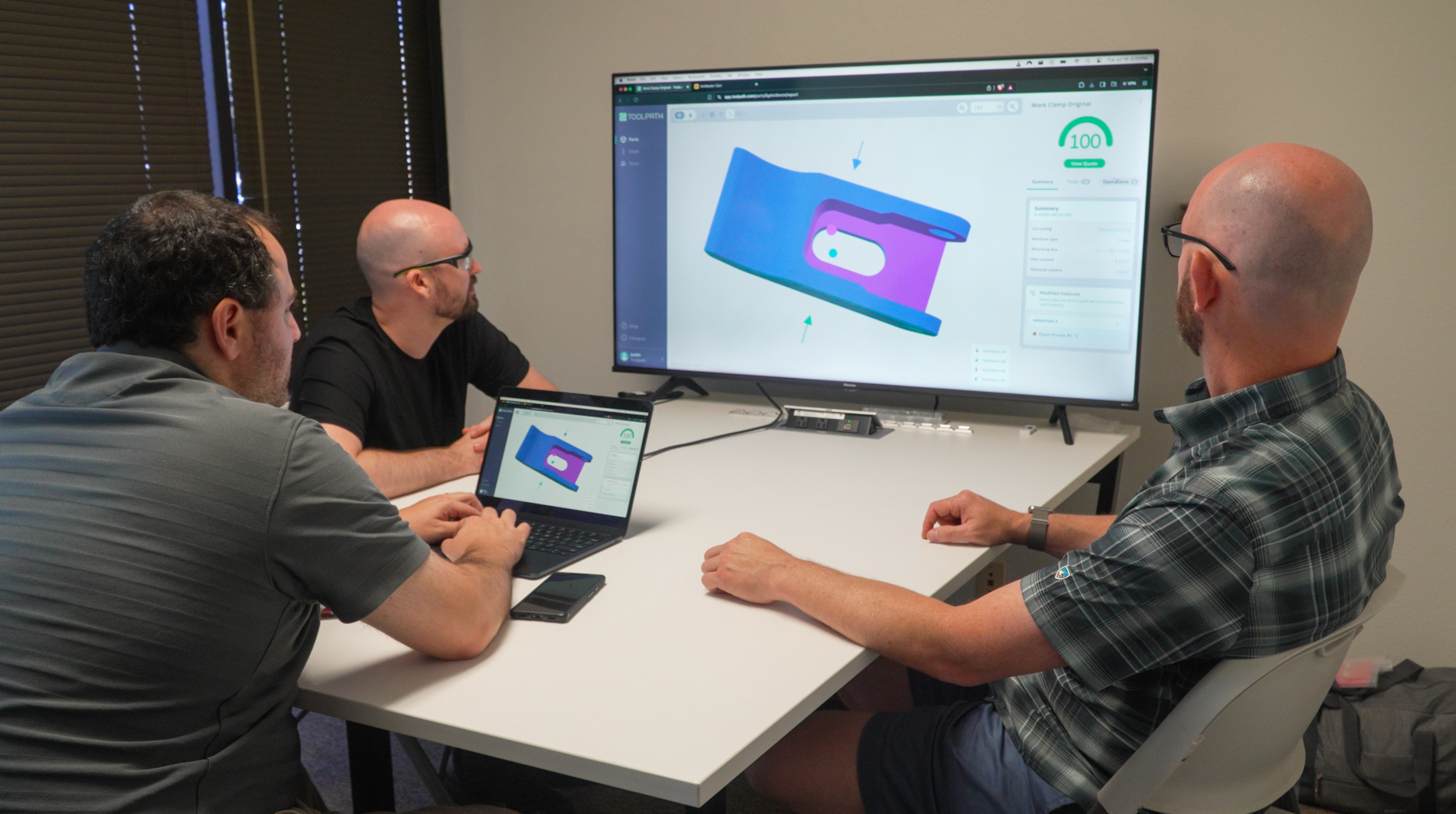

As manufacturing technology continues to advance, the distinction between traditional CAM software and modern, AI-enhanced solutions grows more pronounced. At Toolpath, we're focused on bridging this gap by combining powerful automation capabilities with intuitive usability. Our platform integrates seamless workflow management with AI-driven optimizations, helping shops of all sizes achieve enterprise-level efficiency.

Choosing the right CAM software is a crucial decision that requires careful consideration of your specific needs, growth plans, and operational requirements. While each solution on this list has its strengths, the best choice for your shop will depend on various factors, including your typical projects, existing workflow, and future goals.

Ready to explore how modern CAM software can transform your operations? Start your free trial with Toolpath today and experience firsthand how intelligent automation can revolutionize your manufacturing processes.

Market share data and statistics are based on recent industry analyses by CIMdata in 2023 and may vary by region and industry sector.

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

If you’re working adjacent to CNC machining, you’ve probably heard the terms CAD, CAM, and automation tossed around. While these tools are often...

If you run a CNC shop or work as a machinist, you’re likely aware of CAM (Computer-Aided Manufacturing) software. Today, more shops are exploring how...

Choosing the right CAM (Computer-Aided Manufacturing) software isn’t just about picking a tool; it’s about finding a solution that fits your...

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...