What software works best when operating a CNC?

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

Choosing the right CAM (Computer-Aided Manufacturing) software isn’t just about picking a tool; it’s about finding a solution that fits your workflow, meets industry standards, and helps boost efficiency. With various options available, understanding which features and capabilities align with your unique needs is key. Whether you’re a high-volume shop, a low-volume operation, or an Original Equipment Manufacturer (OEM), Original Design Manufacturer (ODM), or Original Brand Manufacturer (OBM), here are some critical points to consider.

Before comparing products, knowing what makes great CAM software is important. Here are the essential features to consider:

CAM automation is designed to simplify complex processes. Look for software that:

Seamless integration between your design (CAD) and production (CNC) stages is critical. Good CAM software should:

Accessing your projects from anywhere can be a game-changer in today's connected world. Look for software that offers:

AI is starting to play a significant role in CAM software by:

Even if you’re a smaller operation, your CAM software should grow with your business. Look for solutions that offer:

Your shop’s specific requirements can greatly influence the best choice in CAM software. Consider the following:

At its core, CAM software is meant to make machining more efficient and accurate. Features such as CNC programming automation remove much of the guesswork, ensuring that:

For more insights on maximizing your CAM system, explore Mastering CAM Automation: A Guide For CNC Shops.

When evaluating different CAM solutions, keep these factors in mind:

Even the best software needs to be paired with smart strategies:

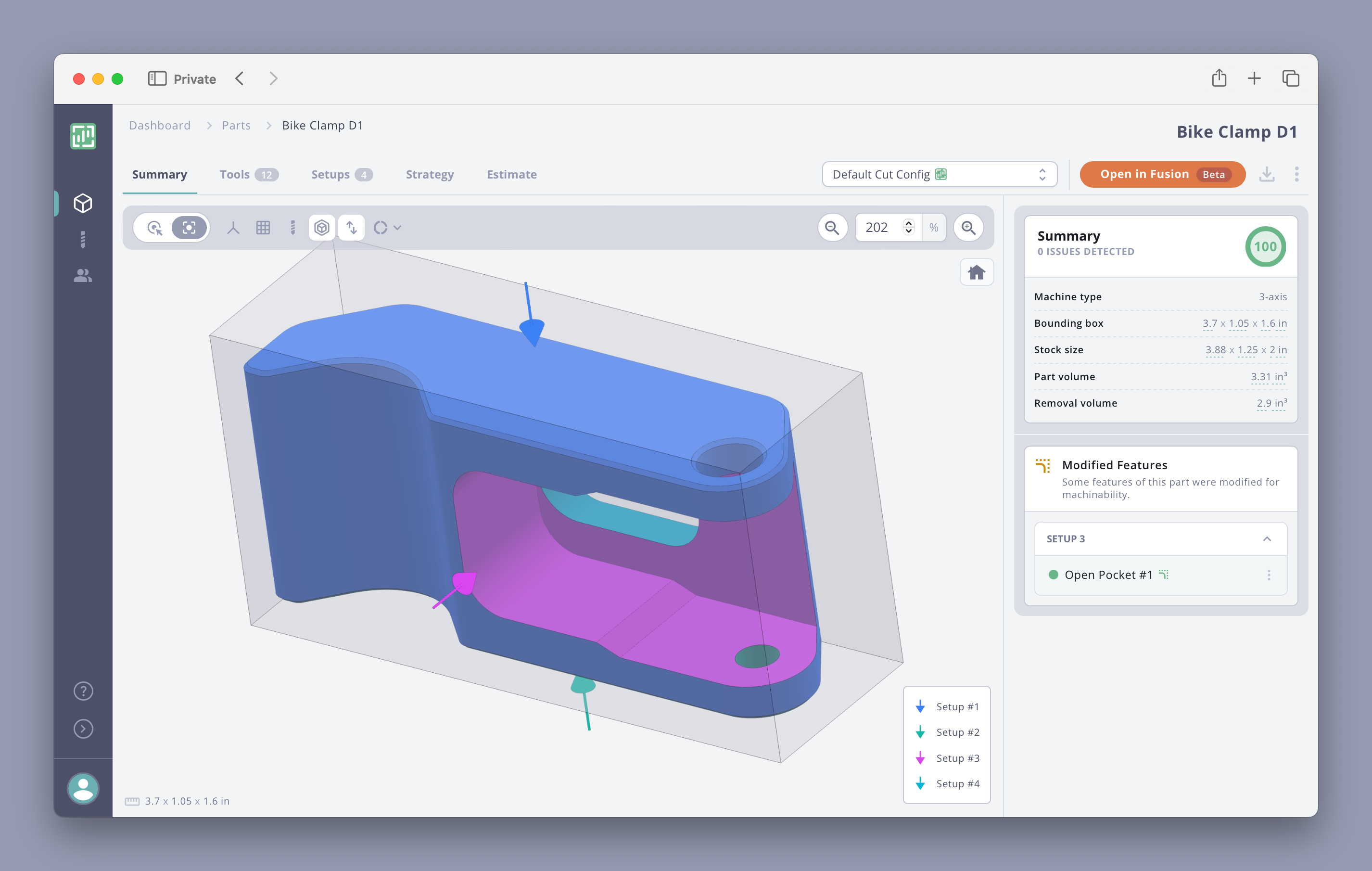

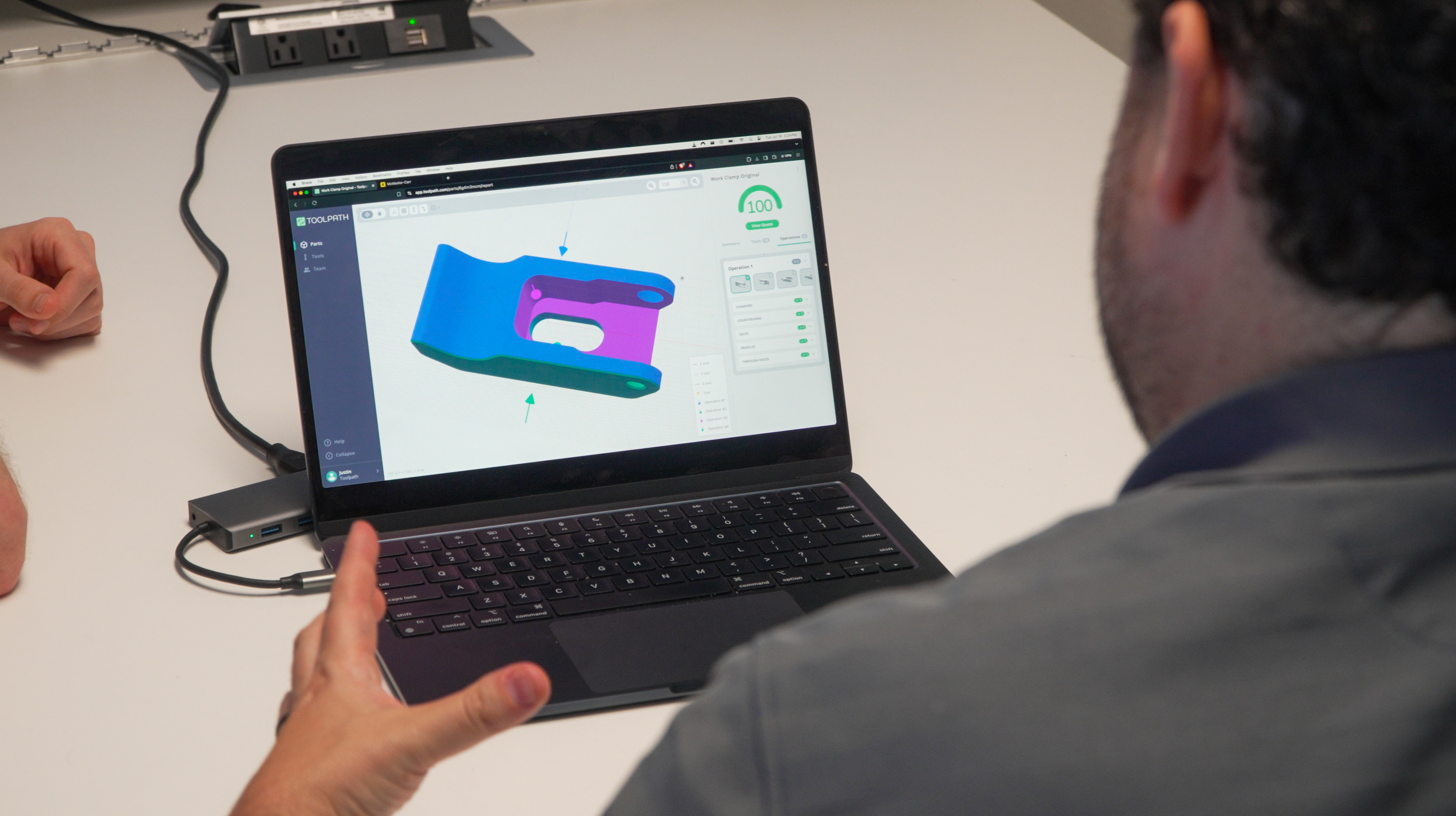

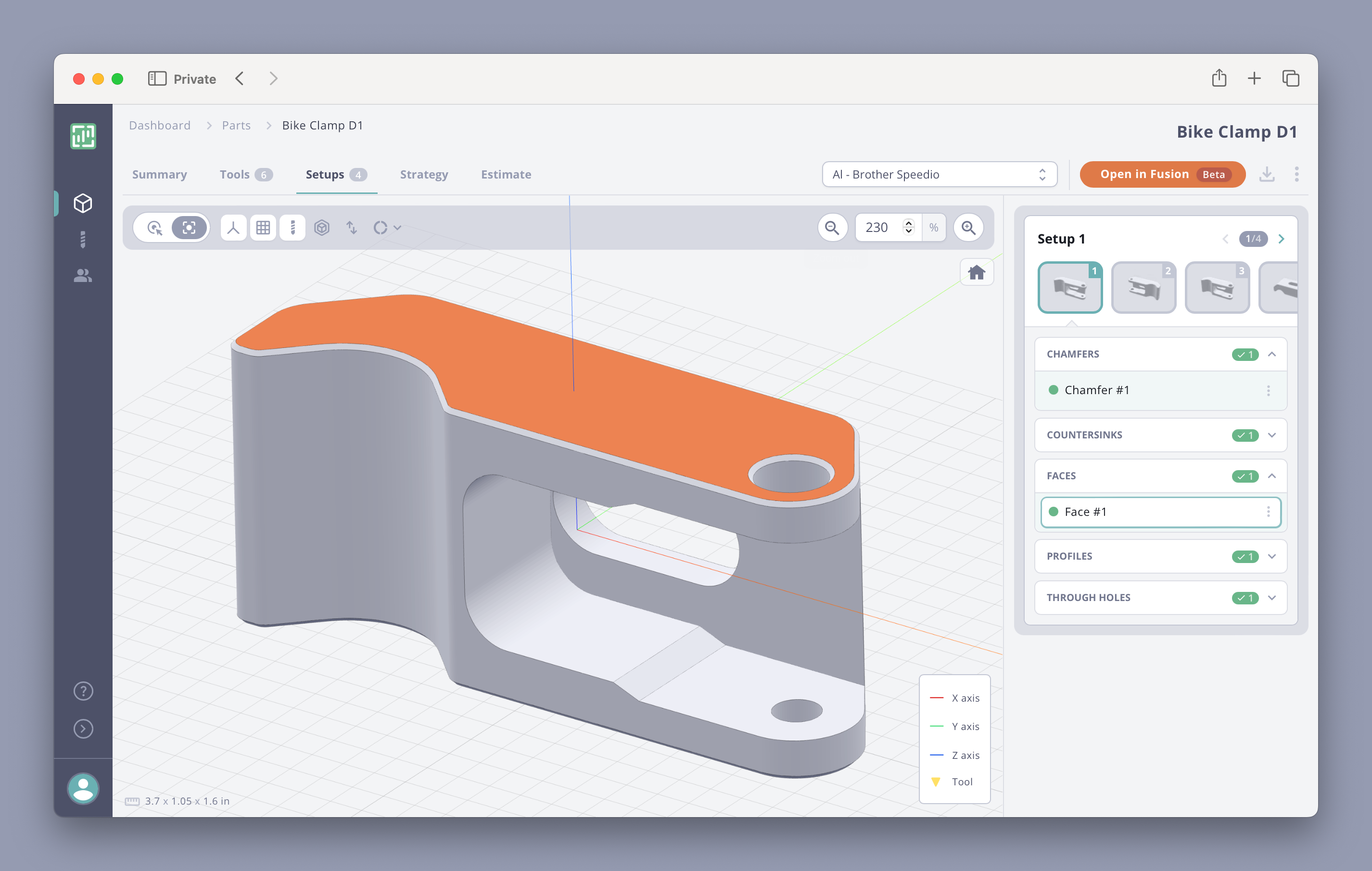

Regarding CAM software, Toolpath checks all the boxes for a modern machine shop. Here’s why:

The best CAM software isn’t a one-size-fits-all solution. It’s the one that meets your unique requirements—whether that means adhering to strict compliance standards, managing varying production volumes, or supporting a distributed workforce. By carefully considering automation capabilities, integration, cloud accessibility, and support, you can find a solution that enhances efficiency, improves precision, and drives growth.

Ready to discover how the right CAM software can transform your CNC operations? Explore Toolpath’s features with a free trial and see firsthand why machinists trust Toolpath to power their shops today.

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

In the world of manufacturing, efficiency is the name of the game. The more efficiently you can produce high-quality parts, the more competitive your...

In today's rapidly evolving manufacturing landscape, choosing the right Computer-Aided Manufacturing (CAM) software can make or break your CNC shop's...

If you’re working adjacent to CNC machining, you’ve probably heard the terms CAD, CAM, and automation tossed around. While these tools are often...

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....