What are the top 10 CAM softwares?

In today's rapidly evolving manufacturing landscape, choosing the right Computer-Aided Manufacturing (CAM) software can make or break your CNC shop's...

If you run a CNC shop or work as a machinist, you’re likely aware of CAM (Computer-Aided Manufacturing) software. Today, more shops are exploring how CAM automation can simplify everyday tasks, streamline processes, and even help small operations compete with bigger players. Let’s dive into five practical advantages of CAM automation and see why it’s a smart investment for your business.

One of the most noticeable benefits of CAM automation is the boost in efficiency. When your CAM software handles routine tasks, you get more time to focus on your work's creative and complex aspects.

Our take: Embracing efficiency through automation means spending less time on repetitive tasks and more time on innovation, a win-win for busy machinists.

Precision is the cornerstone of successful CNC machining, and automating your programming tasks can take your accuracy to a whole new level.

Our take: While no tool is a substitute for skilled human oversight, automation in programming can serve as a reliable safety net, ensuring that precision isn’t compromised.

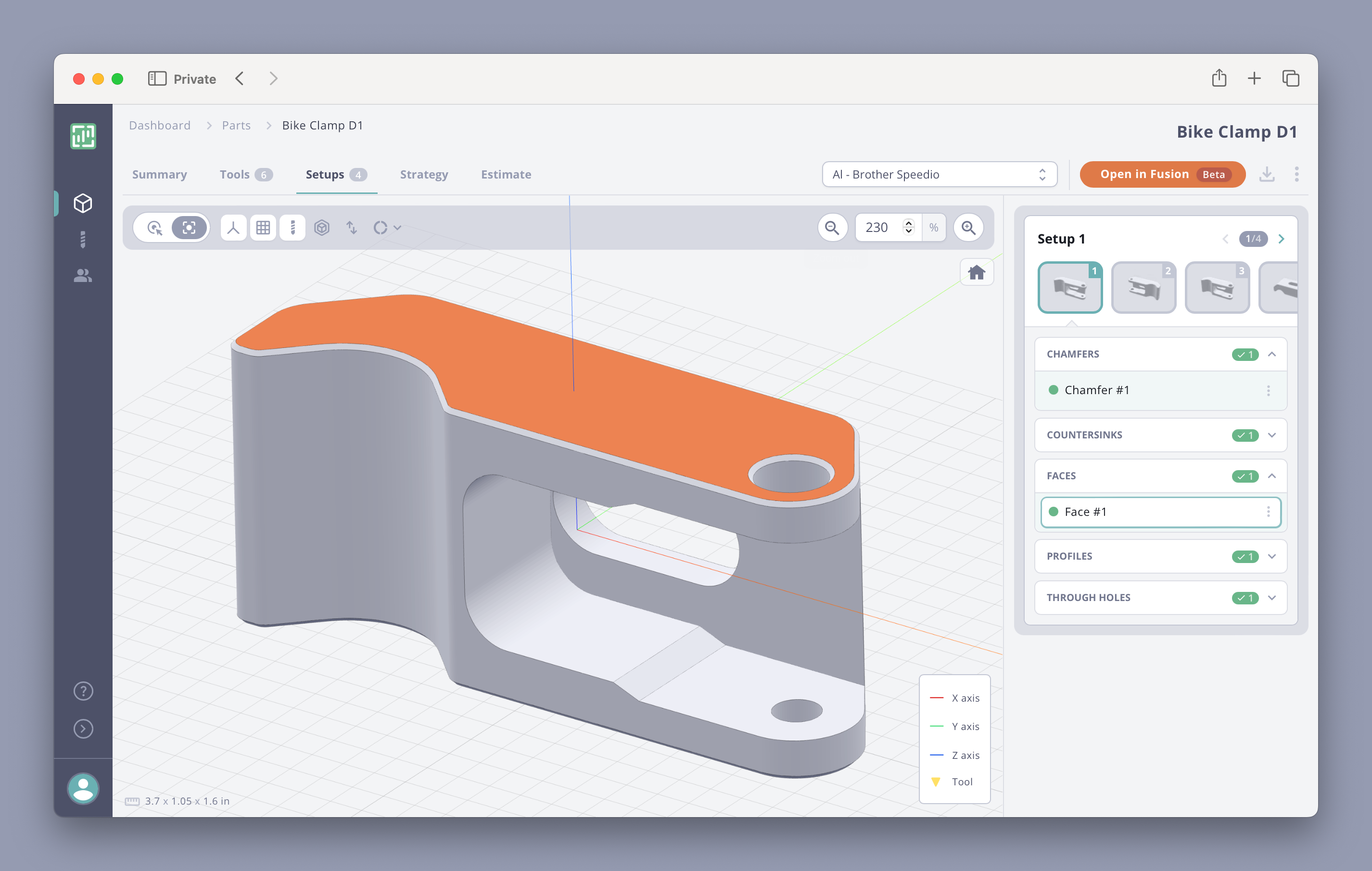

Another big advantage of CAM automation is how it bridges the gap between design and production. By creating a smooth transition from CAD (Computer-Aided Design) to CNC machining, CAM automation makes your entire process more integrated.

Our take: When your design and production teams speak the same language, projects flow more naturally, leading to better outcomes and fewer hiccups.

For shops planning to grow, cloud-based CAM solutions offer the flexibility you need without the heavy investment in new hardware.

Our take: Cloud-based CAM solutions offer a future-proof way to grow your business without being bogged down by the limitations of traditional hardware.

Investing in CAM automation isn’t just about making your workflow smoother; it also directly impacts your bottom line.

Our take: When every penny counts, the cost savings offered by intelligent CNC programming can make a substantial difference, especially for small to medium-sized shops.

Whether you’re a small operation looking to level the playing field or a larger shop aiming for improved turnaround times, CAM automation can make a significant impact:

Want to dive deeper into this topic? Check out our comprehensive guide: Mastering CAM Automation: A Guide For CNC Shops.

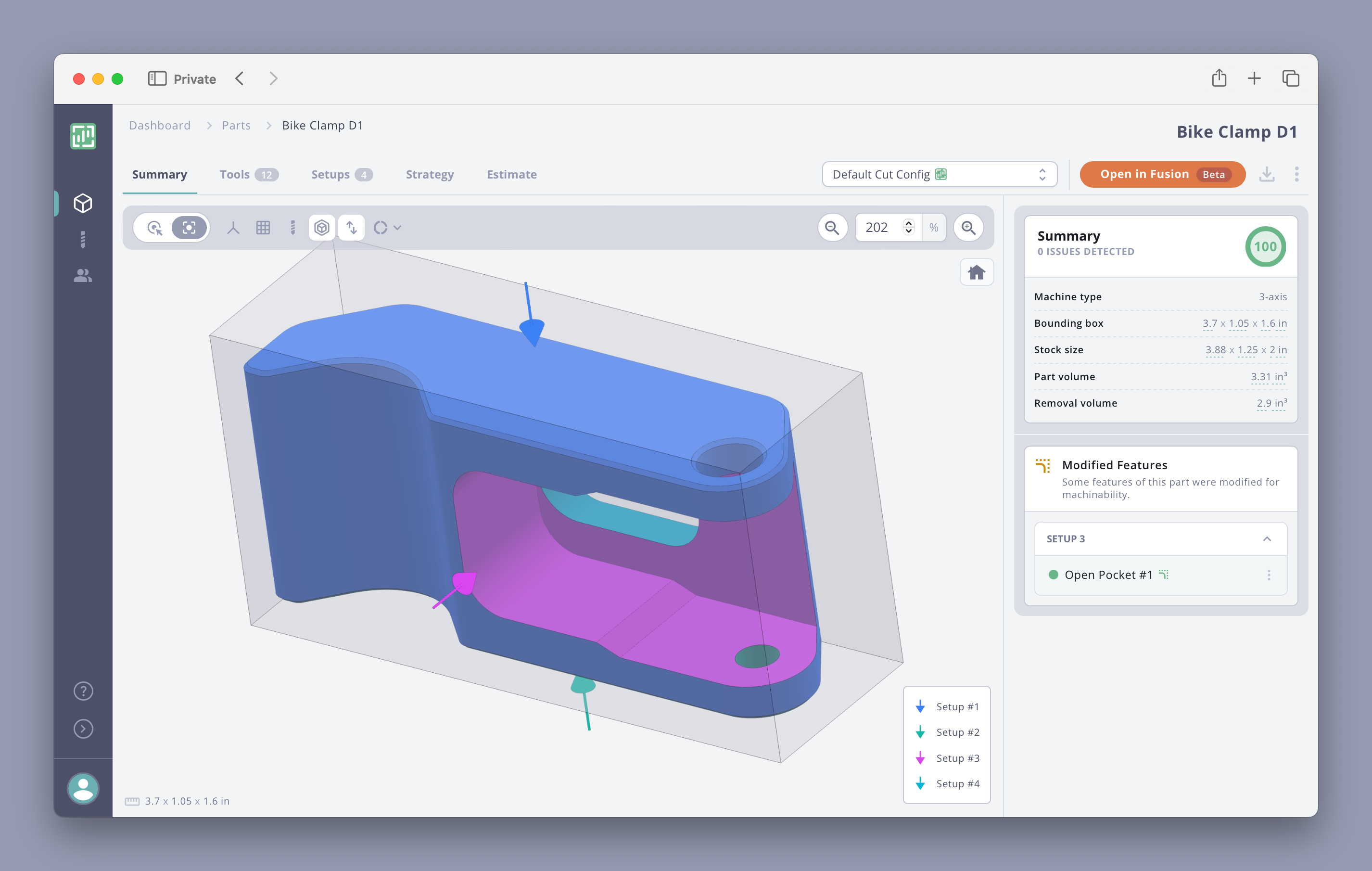

While many CAM solutions offer these advantages, Toolpath brings a unique approach to the table. Here’s how:

Our take: Toolpath’s approach keeps you firmly grounded in what’s possible right now while still offering a glimpse into the exciting potential of AI-assisted machining.

CAM automation isn’t a futuristic concept; it’s a practical tool that can help you work smarter, not harder. The advantages are clear, from enhancing efficiency and precision to integrating workflows and cutting costs. Whether you’re just starting out or looking to scale your operation, CAM automation offers a real-world solution to many of the challenges in today’s manufacturing environment.

Are you curious to see how CAM automation can transform your shop? It might be time to explore a solution designed to meet today’s needs while keeping an eye on tomorrow’s possibilities. Trial Toolpath for Free today!

In today's rapidly evolving manufacturing landscape, choosing the right Computer-Aided Manufacturing (CAM) software can make or break your CNC shop's...

When it comes to operating a CNC machine, having the right software is crucial for smooth, efficient, and accurate machining. The best CNC software...

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating...

If you’re working adjacent to CNC machining, you’ve probably heard the terms CAD, CAM, and automation tossed around. While these tools are often...

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....

In the competitive manufacturing world, CNC machine shops always look for ways to boost productivity and stay ahead of the game. You can...