What is one benefit of the CAM system?

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....

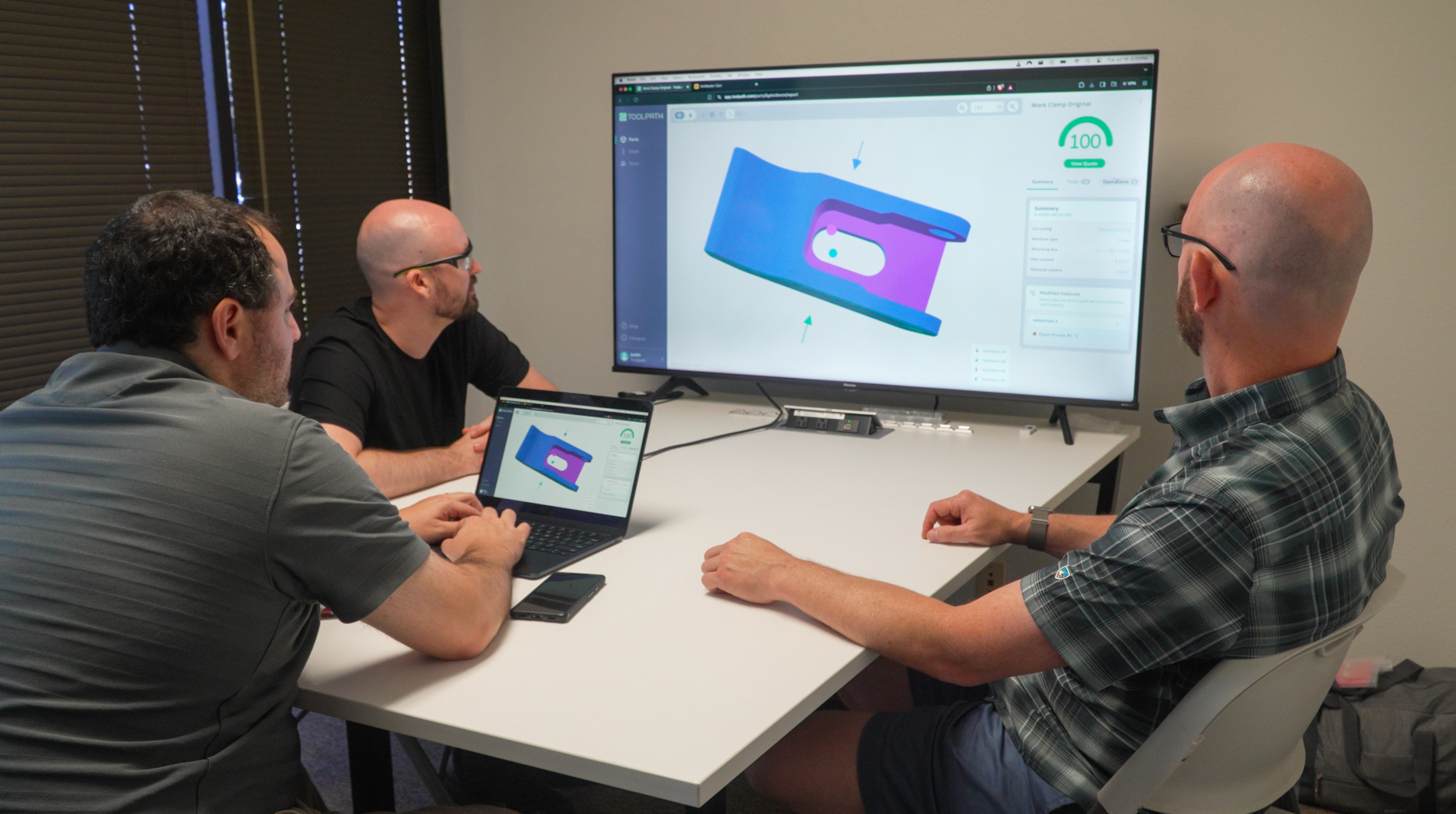

Are you new to CNC machining and wondering about CAM software? Think of CAM (Computer-Aided Manufacturing) as your skilled interpreter, translating complex design ideas into language that CNC machines can understand and follow. This post will walk you through everything you need to know about CAM software's role in the CNC area.

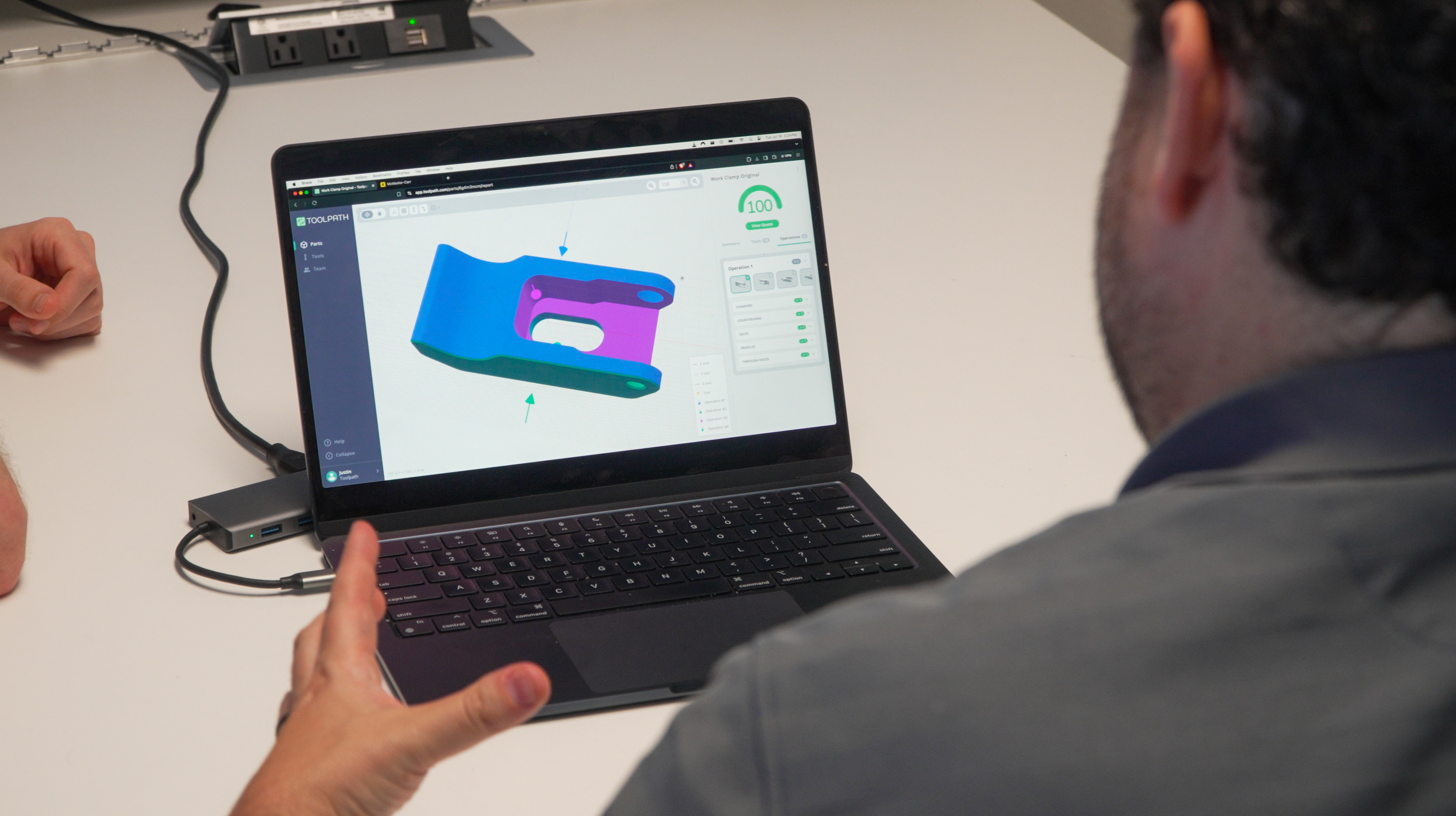

At its core, CAM software is designed to convert CAD (Computer-Aided Design) models into machine-readable instructions. These instructions, often in the form of G-code, guide CNC machines to perform precise cutting, drilling, or shaping operations.

Think of it like this: if CAD software is the tool used to create the blueprint for a part, CAM software is the tool that translates that blueprint into a language that CNC machines can understand and execute.

But modern CAM tools go far beyond basic programming. They offer advanced features like:

These features streamline every aspect of the machining process, from toolpath generation to process optimization.

When you're starting in CNC machining, one of the biggest challenges is knowing which tools to use and how to use them correctly. This is where CAM software's built-in libraries become invaluable. These libraries store detailed information about cutting tools, including their geometry and recommended cutting parameters. Think of it as having a comprehensive cookbook that tells you exactly which tool to use and how to use it for perfect results every time.

Job planning and estimating features help you answer crucial questions before starting any project: How long will this take? How much material do I need? What will it cost? The software analyzes your design and provides accurate estimates, helping you avoid costly surprises down the road.

One of the most revolutionary features in modern CAM software is the ability to create digital twins - exact virtual copies of your CNC machines. This technology lets you simulate and test your entire machining process in a risk-free virtual environment before cutting any actual material. It's like having a practice run in a simulator before performing the real operation, helping you catch and fix potential problems before they occur.

Modern CAM software often comes with cloud-based capabilities, allowing you to access your projects from anywhere with an internet connection. For more insights into how cloud technology is transforming machining, check out our detailed guide on Benefits Of Cloud-Based CAM Solutions For Machinists.

Integrated artificial intelligence in CAM software acts like a keen apprentice who's always open to being trained and sharing their point of view. It analyzes countless part features to suggest optimal cutting speeds, tool paths, and machining strategies. This AI assistance is valuable experienced machinists but also for newcomers to CNC machining, it introduces a high degree of consistency, helping to prevent common mistakes and suggesting proven solutions unique to your workshop.

CAM automation transforms complex programming tasks into straightforward operations. Instead of spending hours manually programming each cut, the software can generate efficient toolpaths automatically. This automation ensures:

Whether you're just starting or looking to improve your existing processes, implementing CAM software effectively is crucial. Key areas to focus on include:

Start with fundamental features before moving to advanced capabilities. Master the basics of toolpath creation and what it takes to get a g-code file out to the CNC machine.

Take time to set up your tooling libraries properly. This initial investment pays off in faster setup times and more consistent results for future projects. Keep an eye on our Blog for tips and best practices on tool library structure and management.

Use digital twin capabilities to test and refine your programs virtually, saving time and materials while building confidence in your processes.

Our comprehensive guide, Mastering CAM Automation: A Guide For CNC Shops, provides detailed strategies for success.

To fully benefit from CAM software, consider these practical tips:

As CAM software continues to evolve, features like AI optimization and digital twin simulation are becoming more sophisticated and user-friendly. These advancements make it easier than ever for newcomers to achieve professional results while helping experienced machinists increase their productivity.

Understanding CAM software might seem overwhelming at first, but it's an invaluable tool that will transform how you approach CNC machining. Start your free trial of Toolpath today and discover how our intuitive, feature-rich platform can help you master CNC machining, whether you're just starting out or looking to enhance your existing operations.

When it comes to Computer-Aided Manufacturing (CAM) systems, it's easy to get caught up in the multitude of features and capabilities they offer....

Picture this: You're a machinist tasked with creating a complex part, one with intricate curves, tight tolerances, and a deadline that's fast...

In the fast-paced world of modern manufacturing, Computer-Aided Manufacturing (CAM) software has become an indispensable tool for enhancing...

In the competitive manufacturing world, CNC machine shops always look for ways to boost productivity and stay ahead of the game. You can...

In the world of manufacturing, efficiency is the name of the game. The more efficiently you can produce high-quality parts, the more competitive your...

CNC (Computer Numerical Control) technology has become the backbone of modern manufacturing automation. CNC machines have revolutionized the way...